Researchers have made unparalleled ultrawide-bandgap semiconductors through temperature and timing, just like baking bread.

Alloying, the process of mixing metals in different ratios, has been a known method for creating materials with enhanced properties for thousands of years, ever since copper and tin were combined to form the much harder bronze. Despite its age, this technology remains at the heart of modern electronics and optics industries. Semiconducting alloys, for instance, can be engineered to optimize a device’s electrical, mechanical and optical properties.

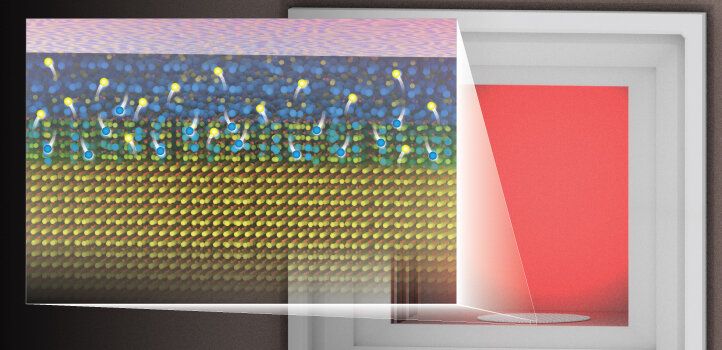

Alloys of oxygen with group III elements, such as aluminum, gallium, and indium, are important semiconductor materials with vast applications in high-power electronics, solar-blind photodetectors and transparent devices. The defining property of a semiconductor is its bandgap, a barrier over which only electrons with the required energy can pass. Beta-phase aluminum gallium oxides are notable because of their relatively large bandgap, but most III-O alloys are expensive to make and of unsatisfactory quality.