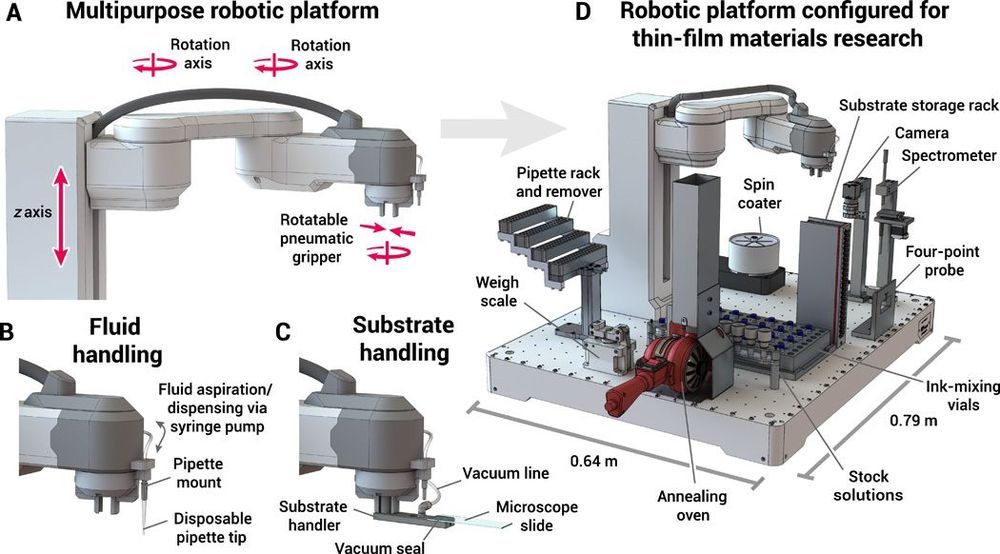

Discovering and optimizing commercially viable materials for clean energy applications typically takes more than a decade. Self-driving laboratories that iteratively design, execute, and learn from materials science experiments in a fully autonomous loop present an opportunity to accelerate this research process. We report here a modular robotic platform driven by a model-based optimization algorithm capable of autonomously optimizing the optical and electronic properties of thin-film materials by modifying the film composition and processing conditions. We demonstrate the power of this platform by using it to maximize the hole mobility of organic hole transport materials commonly used in perovskite solar cells and consumer electronics. This demonstration highlights the possibilities of using autonomous laboratories to discover organic and inorganic materials relevant to materials sciences and clean energy technologies.

Optimizing the properties of thin films is time intensive because of the large number of compositional, deposition, and processing parameters available (1, 2). These parameters are often correlated and can have a profound effect on the structure and physical properties of the film and any adjacent layers present in a device. There exist few computational tools for predicting the properties of materials with compositional and structural disorder, and thus, the materials discovery process still relies heavily on empirical data. High-throughput experimentation (HTE) is an established method for sampling a large parameter space (4, 5), but it is still nearly impossible to sample the full set of combinatorial parameters available for thin films. Parallelized methodologies are also constrained by the experimental techniques that can be used effectively in practice.