Solar energy has long been considered the most sustainable option for replacing our dependence on fossil fuels, but technologies for converting solar energy into electricity must be both efficient and inexpensive.

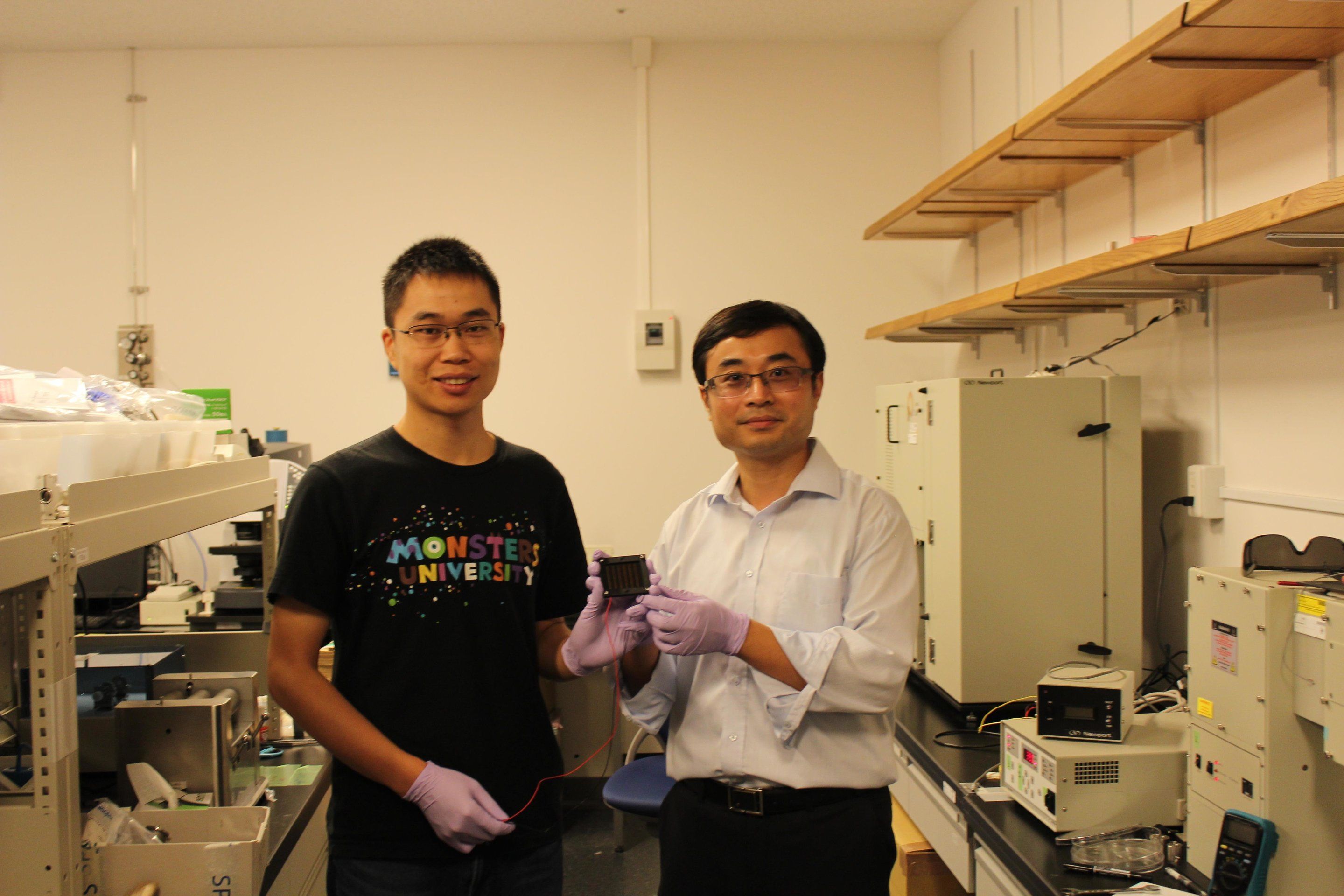

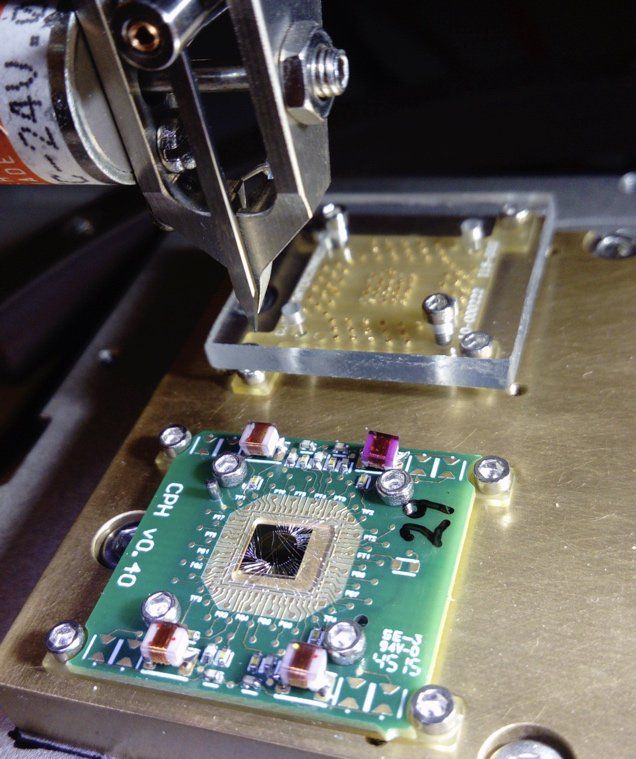

Scientists from the Energy Materials and Surface Sciences Unit at the Okinawa Institute of Science and Technology Graduate University (OIST) believe they’ve found a winning formula in a new method to fabricate low-cost high-efficiency solar cells. Prof. Yabing Qi and his team from OIST in collaboration with Prof. Shengzhong Liu from Shaanxi Normal University, China, developed the cells using the materials and compounds that mimic the crystalline structure of the naturally occurring mineral perovskite. They describe their technique in a study published in the journal Nature Communications.

In what Prof. Qi refers to as “the golden triangle,” solar cell technologies need to fulfill three conditions to be worth commercializing: their conversion rate of sunlight into electricity must be high, they must be inexpensive to produce, and they must have a long lifespan. Today, most commercial solar cells are made from crystalline silicon, which has a relatively high efficiency of around 22%. Though silicon, the raw material for these solar cells, is abundant, processing it tends to be complex and shoots up the manufacturing costs, making the finished product expensive.

Read more