Thermoelectric generators convert heat or cold to electricity (and vice-versa). Normally solid-state devices, they can be used in such things as power plants to convert waste heat into additional electrical power, or in small cooling systems that do not need compressors or liquid coolant. However the rigid construction of these devices generally limits their use to flat, even surfaces. In an effort to apply thermal generation capabilities to almost any shape, scientists at the Ulsan National Institute of Science and Technology (UNIST) in Korea claim to have created a thermoelectric coating that can be directly painted onto most surfaces.

Variously known as the Peltier, Seebeck, or Thomson effect, the thermoelectric effect is seen in semiconductor devices that create a voltage when a different temperature is present on each side or, when a voltage is applied to the device, it creates a temperature difference between the two sides. In this instance, the new paint created by the UNIST researchers is used specifically to heat a surface when a voltage is applied.

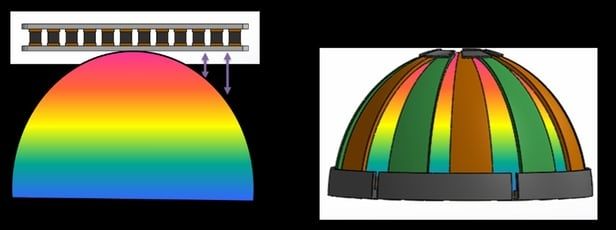

The specially-formulated inorganic thermoelectric paint was created using Bi2Te3 (bismuth telluride) and Sb2Te3 (antimony telluride) particles to create two types of semiconducting material. To test the resultant mixture, the researchers applied alternate p-type (positive) and n-type (negative) layers of the thermoelectric semiconductor paint on a metal dome with electrodes at the top and the base of the dome.