The company aims to commercialize the SD03 in 2025.

Congress is making its biggest push ever to stop drunk driving with President Biden’s huge infrastructure bill. As we previously reported, one of the provisions included a mandate for anti-drunk driving technology in new cars. Now, the Infrastructure Investment and Jobs Act has passed Congress with the measure intact, Autoblog (AP) reports, and it’s expected to be signed by the President soon. As part of the legislation, carmakers will have to include technology to detect and stop drunk drivers by as early as 2026.

First, though, the Department of Transportation will have to determine the best solution to curtail intoxicated drunk driving. Specifically, the bill requires something that will “passively monitor the performance of a driver of a motor vehicle to accurately identify whether that driver may be impaired.” That sounds similar to infrared camera solutions already used today by GM, Nissan and others, Sam Abuelsamid, principal mobility analyst for Guidehouse Insights, tells the AP. It goes without saying that we’d need something more advanced than breathalyzers, which are already used as a punishment for convicted drunken drivers.

Around 10,000 people die every year in the US from drunk driving accidents, the NHTSA says. Now that we have smarter sensors and plenty of camera technology to monitor driver behavior, it makes sense to explore solutions that could help prevent those sorts of accidents. Within a decade, it should feel as commonplace as seatbelts.

The nutrient content of our vegetables is down 40% over the last two decades and our soil health is suffering due to increasingly harsh herbicide use, according to Carbon Robotics founder Paul Mikesell. And farmers are increasingly concerned about the long-term health impacts of continually spraying chemicals on their fields.

But not weeding will cost half your crop, killing profitability.

The solution?

Scientists at Oak Ridge National Laboratory (ORNL) have developed a scalable, low-cost electrochemical pulse method to improve the contact between layers of materials in solid-state batteries, resolving one of the big challenges in the commercial development of safe, long-lived energy storage systems. The new technology could pave the way for electric vehicles and smartphones that work much longer with each charge.

One of the challenges in manufacturing solid-state batteries is the difficulty of getting materials to properly join and remain stable during repeated cycles of charging and discharging. This leads to instability in the joints and causes the formation of voids, something known as contact impedance. Applying high pressures is one way to solve this problem, but that process can lead to shorting and would need to be re-applied periodically to extend the battery’s life using an expensive aftermarket application.

ORNL scientists have found that they could eliminate these voids by applying a short, high-voltage electrochemical pulse when joining layers of lithium metal anode material with a solid electrolyte material. These pulses see a current surrounding the lithium metal-encased voids and cause them to dissipate, leading to increased contact at the interface of the materials while resulting in no detrimental effects.

Solar car is better option.

The influx of electric vehicles into Australia could put an additional load of 20 gigawatts a day — or a doubling of peak electricity demand — on the electricity grid by 2030 if most owners charged up at the same time every night, a new report has found.

The $350 million research collaboration between industry, universities and government has identified a raft of challenges for the arrival of EVs which are expected to make up 80 per cent of new vehicles sales by the end of the decade, making up almost 25 per cent of Australia’s total car fleet.

While there will be huge benefits from taking petrol-guzzling cars off the road, the arrival of EVs – which need to be charged either at home or at public charging stations – creates a range of new headaches, not the least for the electricity grid.

For over a decade, Israeli atmospheric water generator (AWG) company Watergen has been one of the players working to refine and grow air-to-water technology that can efficiently pull water vapor out of the air and collect it as fresh, filtered drinking water. Its previous work has focused heavily on large installations to supply communities, businesses and households, and its latest innovations shrink the water-harvesting tech into a form portable enough for overlanders, RVers, tiny home dwellers and other off-grid explorers.

The last time we ran into Watergen’s work was at CES 2,019 where it showed the Automotive AWG system. The center-console-integrated system was one of the wondrous highlights of the show, but it seemed an odd, limited use for a technology with such potential, a strange detour on a larger journey. Does the average passenger car driver really need a water tap over the cupholders?

If a mobile air-to-water generator is to find a following amongst drivers, it would be a far better fit for vehicles that spend long hours traveling through places without much access to water – motorhomes and camping trailers, specialized remote-work trucks and vans, and perhaps long-haul tractor-trailers, to name a few examples.

US-based Wright Electric has announced a 100-seat electric short-hop aircraft slated to go into service by 2026. It’ll either be powered by hydrogen, or it’ll use recyclable metal in what the company calls an “aluminum fuel cell.”

Wright is working on a number of large electric aircraft projects, including an even bigger 186-seater it’s developing in conjunction with European airline EasyJet and BAE Systems. This would be a “low-emissions” electric, presumably using a fossil-fueled range extender to top up its batteries and extend its flight range to around 1,290 km (800 miles). The partnership is pitching it as a “path” towards clean aviation, a kind of Prius of the skies, that will prove the electric powertrain while waiting for energy storage to come up to scratch.

Wright’s latest project, however, will be totally zero-emissions, and will use high-density energy storage to tackle flights up to an hour in duration – that’s enough for the ~1,000-km (620-mile) hop between Sydney and Melbourne, or London-Geneva, or Tokyo-Osaka, or LA-San Francisco.

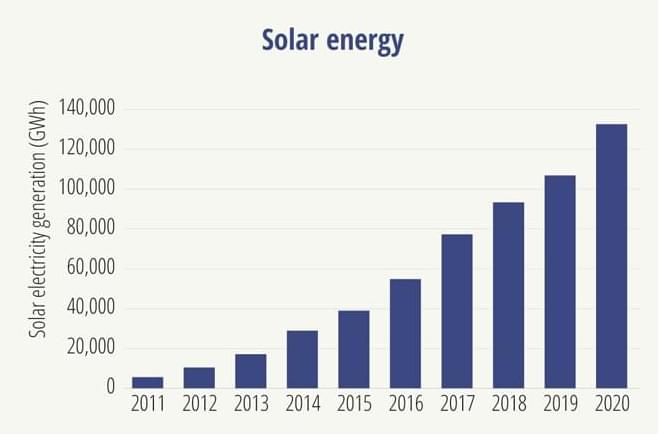

Circa 2020

A newly recruited firefighter in Los Angeles put out a major fire even before being formally introduced at a news conference. That new recruit is a robot.

The Thermite RS3, the first robotic firefighting vehicle in the United States, was scheduled to arrive at the news conference the morning of October 13 but it was diverted to a major emergency structure fire in the fashion district in Downtown Los Angeles earlier that day.

“It was exciting to see this unique piece of apparatus put into action on its first day in service,” said Los Angeles Fire Department Capt. Erik Scott.