Concentrated Solar Power and the better-known photovoltaic panels — what’s the difference, and is one better than the other?

Concentrated Solar Power and the better-known photovoltaic panels — what’s the difference, and is one better than the other?

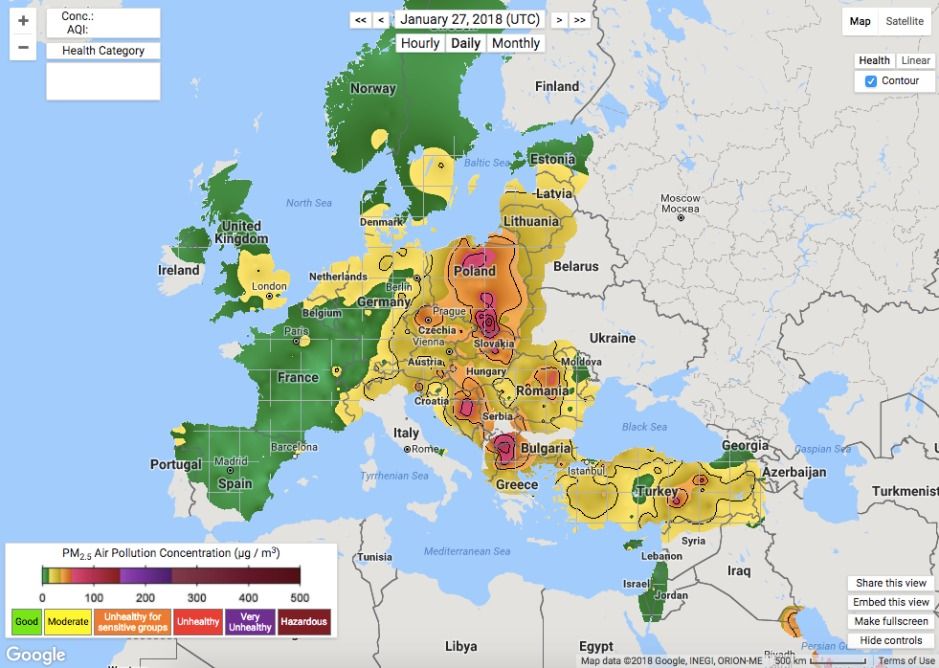

It also causes 800,000 premature deaths in Europe every year, with an ‘Iron Curtain’ dividing East and West.

The central Indian state of Madhya Pradesh set a new Guinness World Record on Sunday after 1.5 million volunteers planted more than 66 million tree saplings in just 12 hours along the Narmada river.

The effort bested the state of Uttar Pradesh’s previous record-breaking feat, when 800,000 participants planted 50 million trees in one day in July 2016.

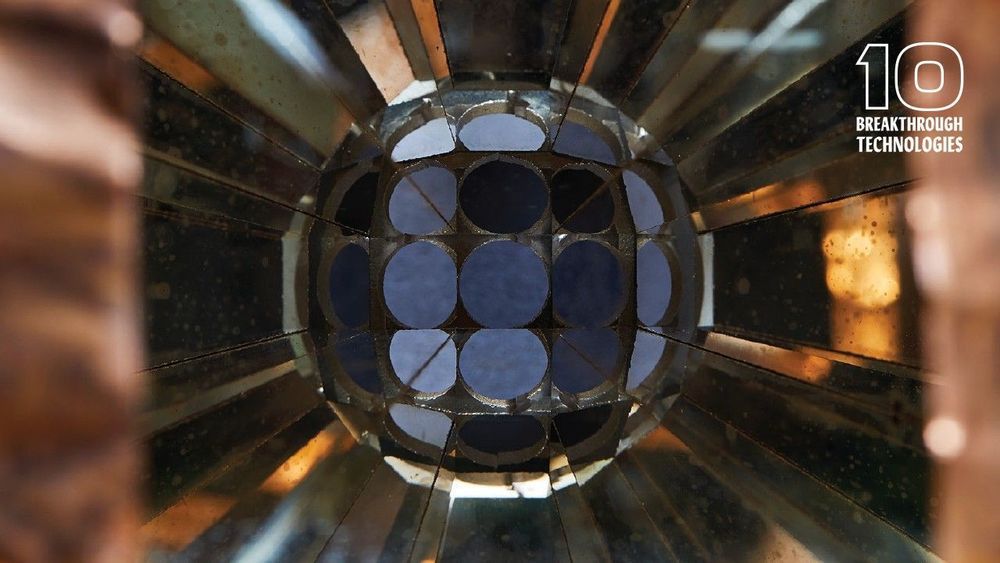

By converting heat to focused beams of light, a new solar device could create cheap and continuous power.

Car Culture

Other automotive name choices include “Ford,” “Bentley,” and “Audi,” as Mashable reports, accounting for thousands of innocent newborns.

Whether the decision will help the car company overcome hurdles like hitting the lowest stock valuation since 2017 or dealing with multiple reports of Teslas randomly catching fire is unknown.

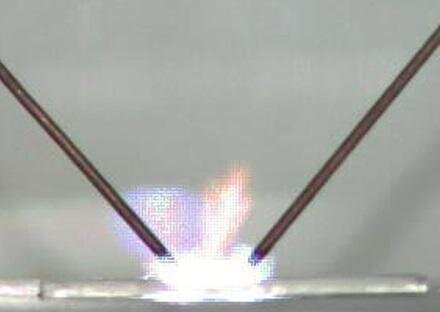

As the number of electronics devices increases around the world, finding effective methods of recycling electronic waste (e-waste) is a growing concern. About 50 million tons of e-waste is generated each year and only 20% of that is recycled. Most of the remaining 80% ends up in a landfill where it can become an environmental problem. Currently, e-waste recycling involves mechanical crushers and chemical baths, which are expensive, and manual labor, which can cause significant health and environmental problems when not performed properly. Thus, researchers from Kumamoto University, Japan have been using pulsed power (pulsed electric discharges) to develop a cleaner and more efficient recycling method.

Pulsed power has been shown to be successful in processing various waste materials, from concrete to waste water. To test its ability to be used in e-waste recycling, researchers examined its effectiveness in separating components found in one of the most prolific types of e-waste, CD ROMs. In previous work, they showed that complete separation of metal from plastic occurred using 30 pulses at about 35 J/pulse (At the current price of electricity in Tokyo, this amount of energy costs about 0.4 Yen for recycling 100 CD ROMs). To examine the mechanism of material separation using this method, researchers performed further analyses by observing the plasma discharge with a high-speed camera, by taking schlieren visualizations to assess the shock wave, and using shadowgraph images to measure fragment motion.

Images at the early stage of electrical discharge showed two distinct light emissions: blue-white and orange. These indicated excitation of aluminum and upper protective plastic materials respectively. After the plasma dissipated, fragments of metal and plastic could be seen flying away from the CD ROM sample.

Air pollution is responsible for millions of deaths every year, worldwide. According to a State of Global Air report, air pollution is the fifth greatest global mortality risk.

“Air pollution is the fifth highest cause of death among all health risks, ranking just below smoking; each year, more people die from air pollution related disease than from road traffic injuries or malaria.”

No wonder, then, that when Google.org issued an open call to organizations around the world to submit ideas for how they could use AI for societal challenges, Google chose one of the 20 winning organizations as one that was out to address pollution.

Circa 2018

A moss capable of removing arsenic from contaminated water has been discovered by researchers from Stockholm University. And it happens quickly — in just one hour, the arsenic level is so low that the water is no longer harmful for people to drink. The study has been published in the journal Environmental Pollution.

The aquatic moss Warnstofia fluitans, which grows in northern Sweden, has the ability to quickly absorb and adsorb arsenic from water. The discovery allows for an environmentally friendly way to purify water of arsenic. One possible scenario is to grow the moss in streams and other watercourses with high levels of arsenic.

Water in mining areas often contaminated

In the northern part of Sweden, water from mining areas is often contaminated by arsenic.

When designing the Tesla Model S, Elon Musk wanted an electric motor that had the same horsepower as the most powerful internal combustion engine but with nearly-instantaneous torque. And he wanted it to be the size of a watermelon. Engine manufacturers told him this couldn’t be done. So the Tesla CEO decided to build his own motor. The earlier versions of this had a hand-wound stator which increased winding density to help eliminate resistance and increase peak torque. Later versions of the stators were built by robots.

Musk made the same decision with practically every other component of the Tesla — including the power electronics and other elements of the drivetrain. For him, there could be no compromises in design and functionality. That is why almost every component of the Tesla Model S is produced at its factory in Fremont, Calif.

When you drive a Model S, you can see the results. The car literally seems to fly. It picks up acceleration like a spaceship shifting into warp speed. The car is eerily quiet, comfortable, and elegant. It is a completely different driving experience than the cars we are used to. There is no engine to start, gears to shift, or oil to replace. The brakes don’t wear out because you hardly use them. The Tesla regenerative-braking system charges the car as it slows.