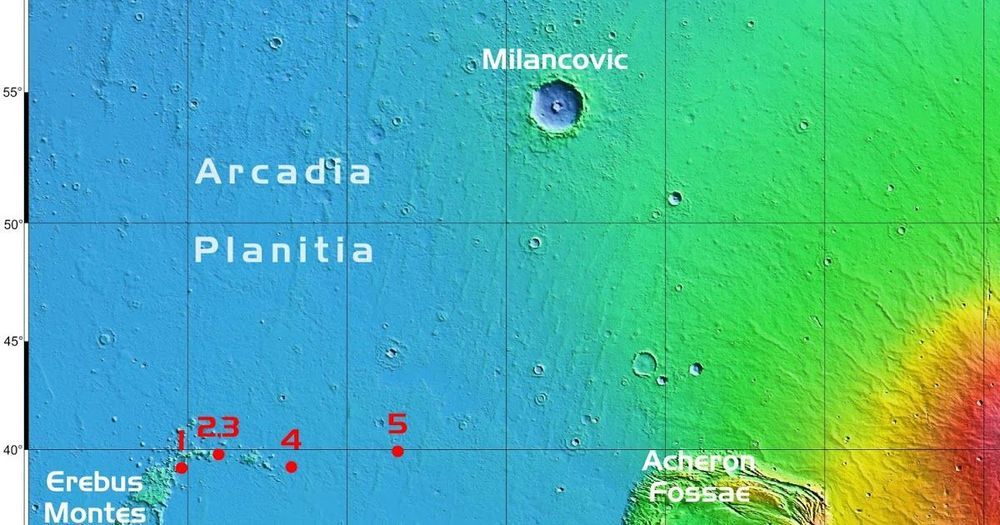

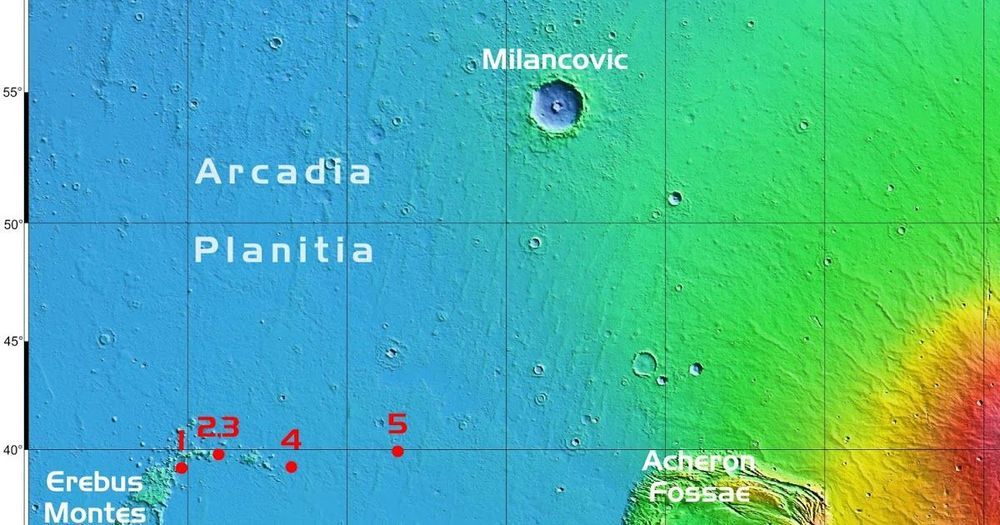

Several images labelled as “Candidate Landing Site for SpaceX Starship in Arcadia Region” were found in the latest data release from University of Arizona.

https://youtu.be/-IaYan29BxY

This is interesting because it has today type applications, but I wonder, what about a 3D printed body? Remember the movie Starship Troopers when they repaired that guy’s leg in the water tank thing? I’ve seen similar devices in other movies. Could be easier than removing the head completely and safer, when the ability to print human tissues is feasible.

GUYS HOPE YOU LIKE THE VIDEO PLEASE LIKE AND SUBSCRIBE TO MY CHANNEL AND HIT THE BELL ICON.

And if you have any question related to the video then please comment down below.

This year marks the 50th anniversary of one of the most pivotal moments in human history. Stepping onto the moon, Neil Armstrong in 1969 uttered those now infamous words: “That’s one small step for man, one giant leap for mankind.”

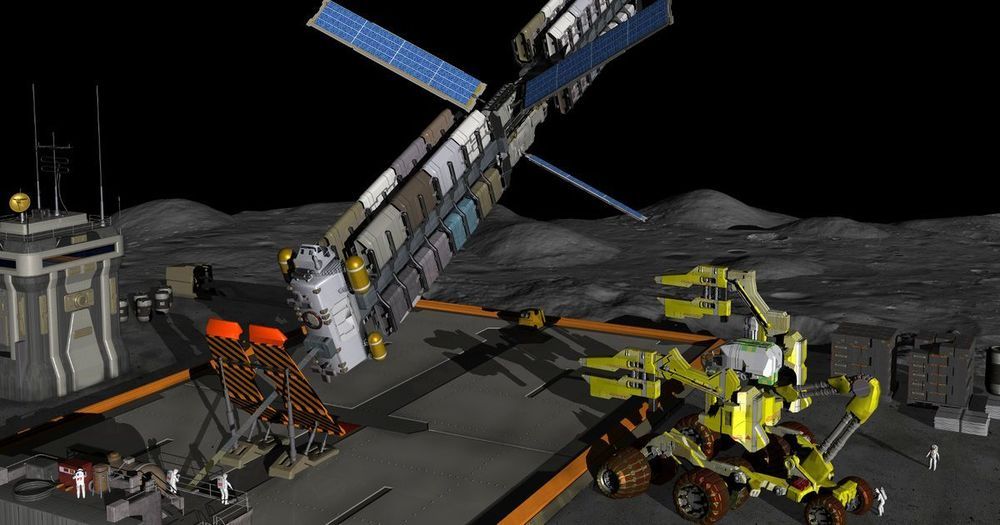

The next fifty years did not see space travel become routine, with many coming to believe that NASA is just too slow. But space-related research and innovation are enjoying a new revival, inspired by SpaceX, Blue Origin, Virgin Galactic, and other private firms that are making commercial space travel a reality. Along with rockets, hundreds of companies across the world are working feverishly toward developing infrastructure for space tourism, novel methods of growing food off-Earth, and sustainable building materials, to name only a few. All this with a tantalizing goal: to open up other planets and extraterrestrial bodies for exploration — and perhaps even residence — by everyone, not just astronauts.

Such work has not only moved us closer to our goal of one day living and playing off-Earth, but has also benefited our lives right here, right now. Scratch-proof glass, some biopharmaceuticals, and GPS navigation all derive from space-based research. The innovation happening today is incredibly exciting, and the future possibilities are seemingly endless. Here are five companies working on technologies that can help us thrive both on- and off-Earth.

There’s been a lot of traffic coming and going around the International Space Station.

WASHINGTON — SpaceX plans to build facilities at the Kennedy Space Center’s Launch Complex 39A for launches and, eventually, landings of its next-generation launch vehicle, according to a newly released report.

An environment assessment prepared by SpaceX, and released by NASA Aug. 1, discusses plans to develop additional facilities at LC-39A, which currently hosts Falcon 9 and Falcon Heavy launches, for use by the company’s Starship vehicle and its Super Heavy booster.

The plans outlined in the document call for the construction of a new launch mount at the complex near the existing one used by the Falcon 9 and Heavy. The modifications to the pad would also include a tank farm for the methane fuel used by the Raptor engines that power Starship and Super Heavy.

Based on some basic analysis of recent photos of SpaceX’s East Coast Starship facility, situated in Cocoa, Florida, SpaceX has almost certainly begun fabricating and staging hardware that will eventually become part of the company’s first Super Heavy booster prototype.

This is by no means surprising but it does confirm the reasonable assumption that SpaceX is already working hard to ensure that the first Super Heavy booster(s) can be assembled as quickly as possible. Additionally, SpaceX appears to have started clearing brush in the process of preparing to transport the Florida orbital Starship prototype (“Mk2”) to SpaceX’s Pad 39A launch facilities, dozens of miles away.

The aforementioned “basic analysis” is more or less comprised of looking for and counting the massive steel rings that SpaceX has decided to build its Starships (and Super Heavy boosters) out of. By all appearances, SpaceX is doing nearly everything short of milling and preparing the raw materials (steel) internally. In Florida and Texas, giant rolls of stainless steel are delivered to the worksite by semi-truck, where SpaceX technicians prepare the rolls for sectioning (likely with a plasma torch or laser) and any necessary machining.

Astronauts would have to fly their rocket into the Spaceline, attach to a solar-powered shuttle and be dragged up to the Moon.

Carbon nanotubes will need to be built on a large scale for the design.

Zephyr Penoyre, one of the Columbia astronomy graduate students behind the Spaceline, told Futurism: The line becomes a piece of infrastructure, much like an early railroad.

Hinted at in a brief tweet on August 28th, SpaceX CEO Elon Musk says that SpaceX’s massive Starship and Super Heavy launch vehicle – set to be the most powerful rocket ever built upon completion – could eventually be followed by a rocket multiple times larger.

SpaceX is currently in the process of assembling the first full-fidelity prototypes of Starship, a 9m (30 ft) diameter, 55m (180 ft) tall reusable spacecraft and upper stage. Two prototypes – Mk1 and Mk2 – are simultaneously being built in Texas and Florida, respectively, while the beginnings of the first Super Heavy prototype has visibly begun to take shape at SpaceX’s Florida campus.

Once complete, Starship’s Super Heavy booster will be the single most powerful rocket booster ever built, standing at least 70m (230 ft) tall on its own and capable of producing as much as ~90,000 kN (19,600,000 lbf) of thrust with 30 250-ton-thrust and 7 200-ton-thrust Raptor engines installed. Assuming 31 throttleable 200-ton Raptors, Super Heavy’s minimum max thrust is a still record-breaking ~62,000 kN (13.7 million lbf).

(SCRUBBED) Watch SpaceX’s Starhopper come alive for the second time, as it attempts a 150 Meter test hover.