Six-hundred million people in Sub-Saharan Africa lack access to electricity. To meet these power needs, a mix of large public-run utility grids and standalone systems will be necessary for universal access in the region. Governments, aid organizations, and scientists are working to understand which electricity grid solution would be most cost-effective and reliable across urban, peri-urban, and rural areas.

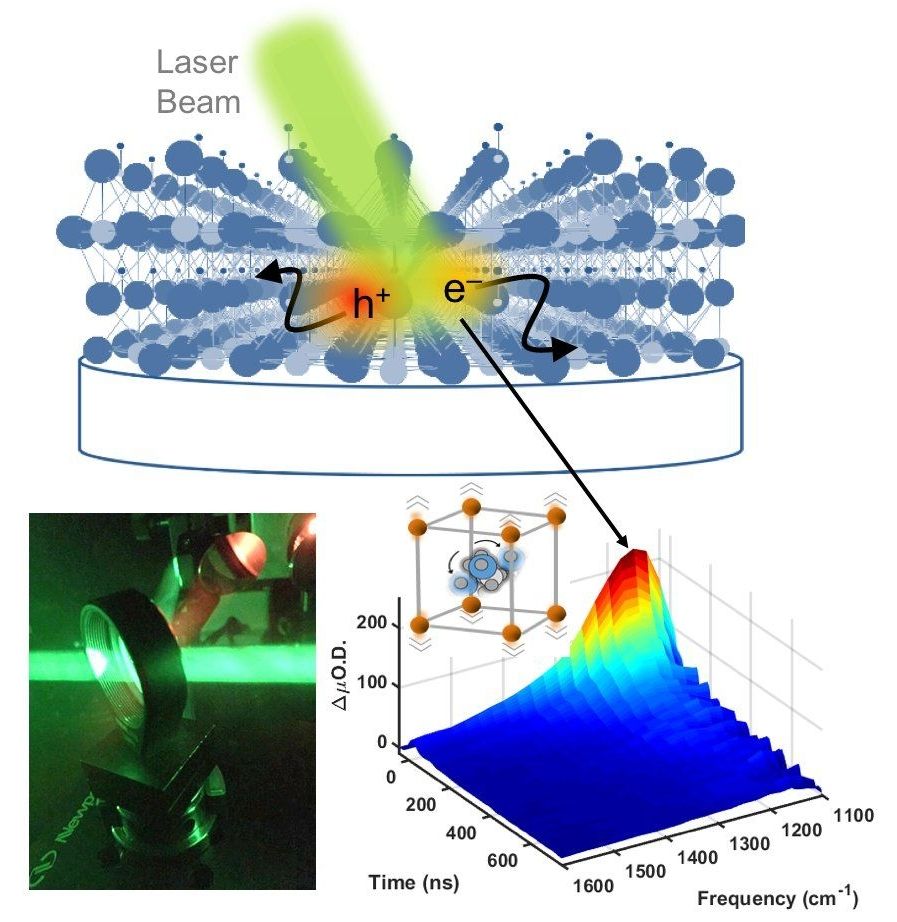

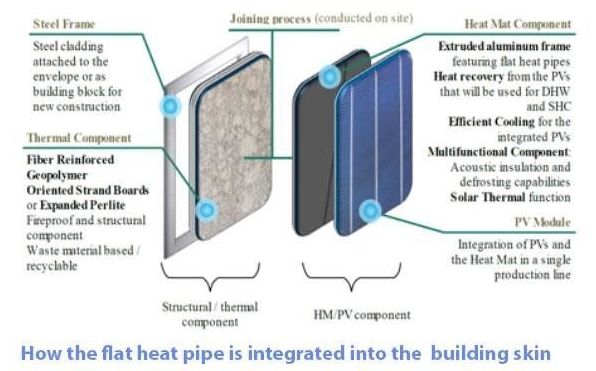

Standalone, or “decentralized” electricity systems—most often solar power with battery storage—are usually thought to be too expensive compared to large state-run grids in all but the most remote locations. However, declining costs of solar and new battery technologies are changing the best pathways to deliver reliable power to people that currently lack access to electricity. New UC Berkeley research published today in Nature Energy finds that decentralized electricity systems in sub-saharan Africa can be designed for extremely high reliability, and that this may come at remarkably low costs in the future.

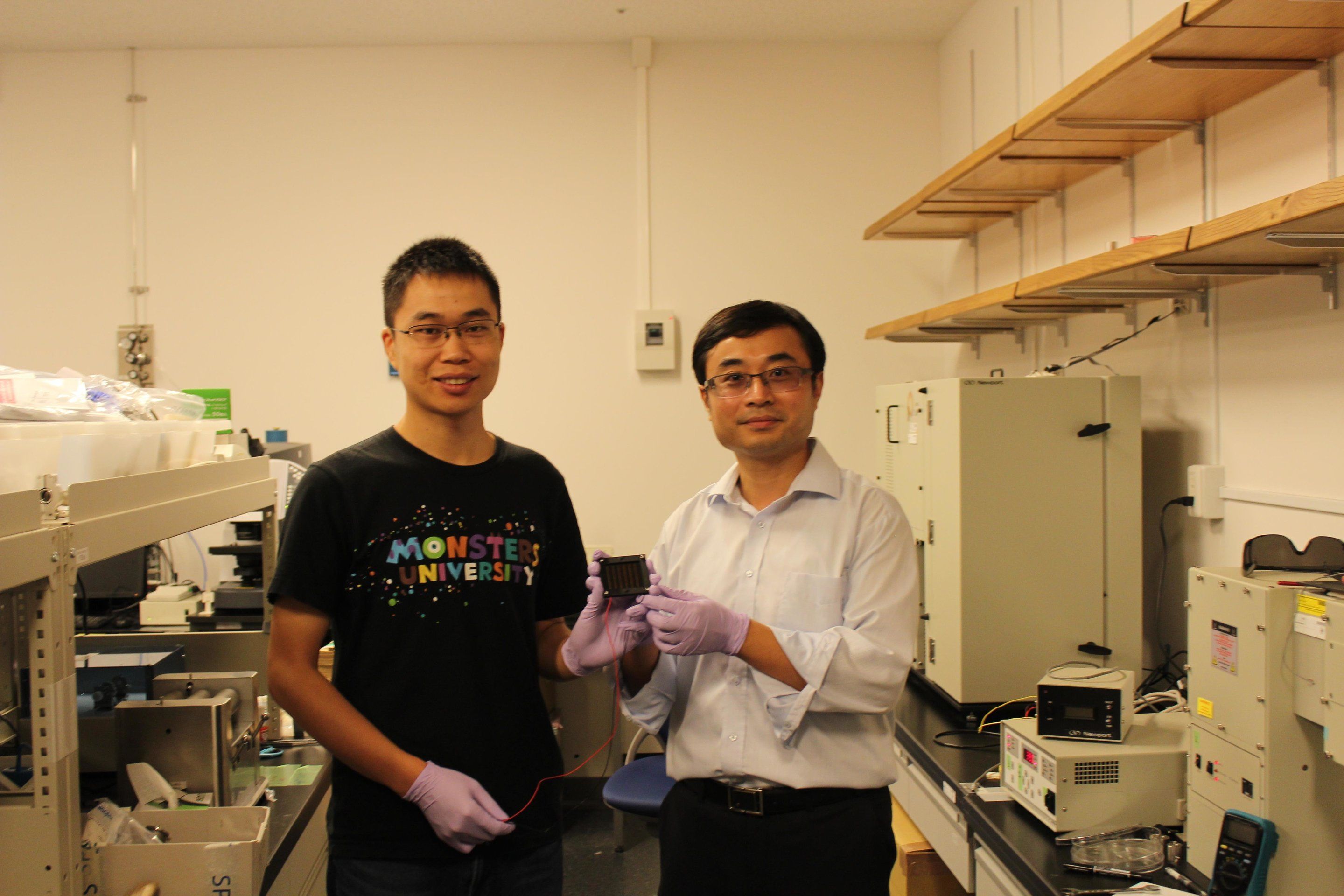

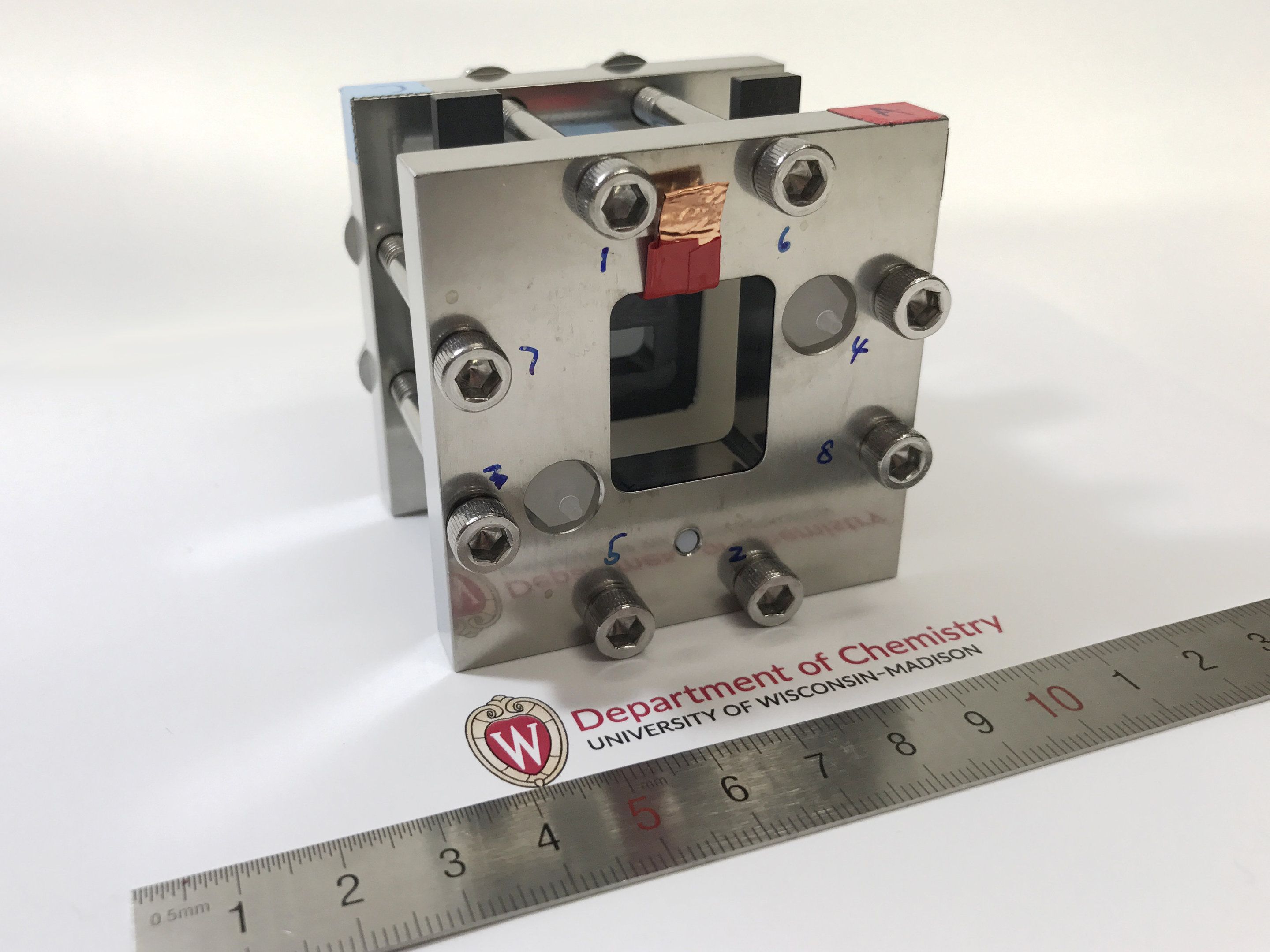

Jonathan Lee, a Ph.D. candidate in the Energy and Resources Group (ERG) and Associate Professor Duncan Callaway worked with more than 10 years of solar data from NASA and developed an optimization model that determines the lowest cost way to build a standalone system given component costs and a target reliability. At current costs, their model indicates that most regions in Sub-Saharan Africa can get 95% reliable power—meaning customers can use electricity from some combination of solar panels and batteries 95% of the time—for roughly USD$0.40 per kWh. Though that cost is high relative to current grid costs, their model indicates that with aggressive but plausible future cost declines in decentralized system costs, largely in batteries, these costs would drop to levels competitive with the grid in many parts of the continent in less than a decade.