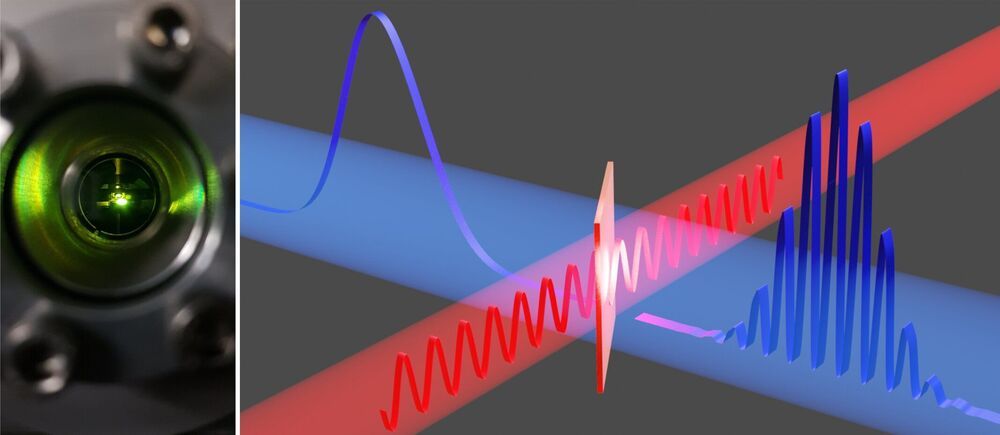

A team of physicists from the University of Konstanz and Ludwig-Maximilians-Universität München in Germany have achieved attosecond time resolution in a transmission electron microscope by combining it with a continuous-wave laser—offering new insights into light-matter interactions.

Electron microscopes provide deep insight into the smallest details of matter and can reveal, for example, the atomic configuration of materials, the structure of proteins or the shape of virus particles. However, most materials in nature are not static and rather interact, move and reshape all the time. One of the most common phenomena is the interaction between light and matter, which is ubiquitous in plants as well as in optical components, solar cells, displays or lasers. These interactions—which are defined by electrons being moved around by the field cycles of a light wave—happen at ultrafast time scales of femtoseconds (10-15 seconds) or even attoseconds (10-18 seconds, a billionth of a billionth of a second). While ultrafast electron microscopy can provide some insight into femtosecond processes, it has not been possible, until now, to visualize the reaction dynamics of light and matter occurring at attosecond speeds.

Now, a team of physicists from the University of Konstanz and Ludwig-Maximilians-Universität München have succeeded in combining a transmission electron microscope with a continuous-wave laser to create a prototypical attosecond electron microscope (A-TEM). The results are reported in the latest issue of Science Advances.