To truly reach a fully connected world/ singularity we have to move tech into more and more bio-computing world. I do believe QC will assist us in getting the fundamental infrastructure we need for singularity.

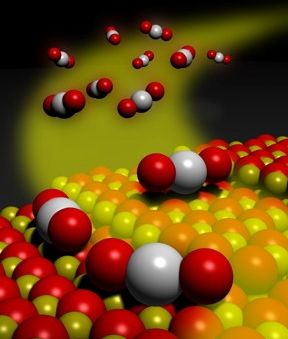

We already must deal with computers too much rather than too little, and there is already lots of advanced computing done also for example in materials science and nanotechnology, for example molecular dynamics (MD) and Monte Carlo simulations.[2] The molecular biologist’s programs for predicting protein folding can also count as nanotechnology. Nevertheless, all of our previous articles concluded that we need more computing, and several mentioned statistics. This would sound predictable if coming from a statistical physicist with a background in computing, advertising his skills. However, we mean a more efficient computing rather than simply more.

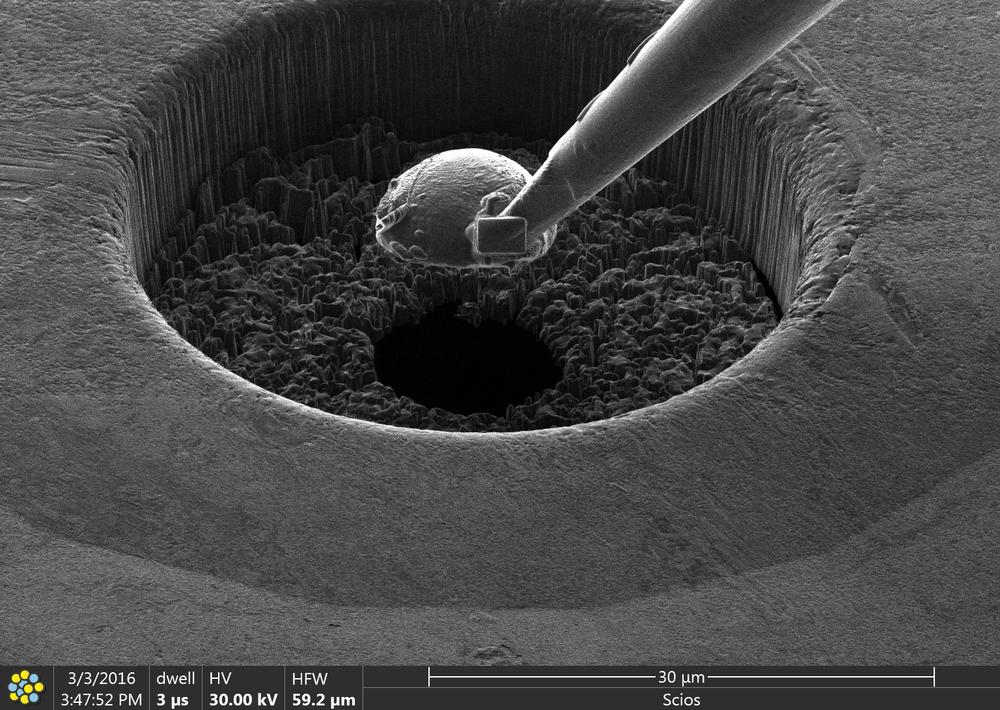

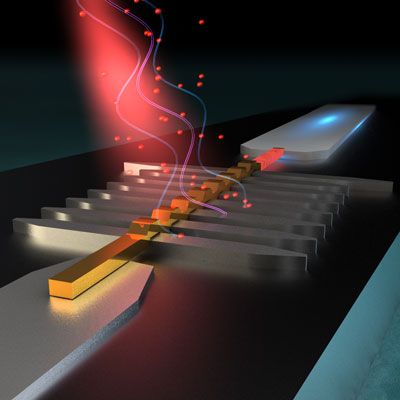

We started the type of computing we do only recently and for reasons not yet mentioned: Given complex nano-micro compounds, materials’ characterization is difficult due to the three-dimensional complexity of the structures. We originally integrated image analysis with simulation in order to derive 3D structure from 2D images (SEM) and projections (TEM).[3,4] The most fruitful result was however the insight into how easy it is to create adaptable software that analyzes images and keeps track of all the data, calculating anything desired such as comparisons with numerical simulations, all in one integrated system.[5,6] Many of the previously discussed issues, for example error reporting, are thereby basically already automatically solved!

Adapting software sounds prohibitively difficult: Who in my lab can modify software? Nowadays everybody! Today, programming is done partially graphically, for example with LabView™, where no programming language appears anymore. We work with Mathematica and therefore with programming code, but we mostly just download parts of code and adapt them playfully until they behave as desired. To whomever such does not count as the ability to program, we cannot program!

Read more