A new kit leaves your cryptographic destiny up to 25 cubes in a plastic box.

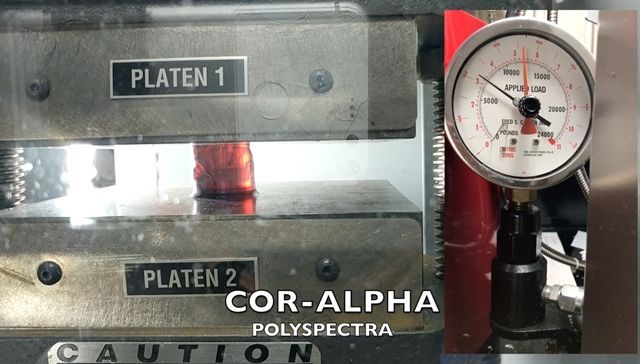

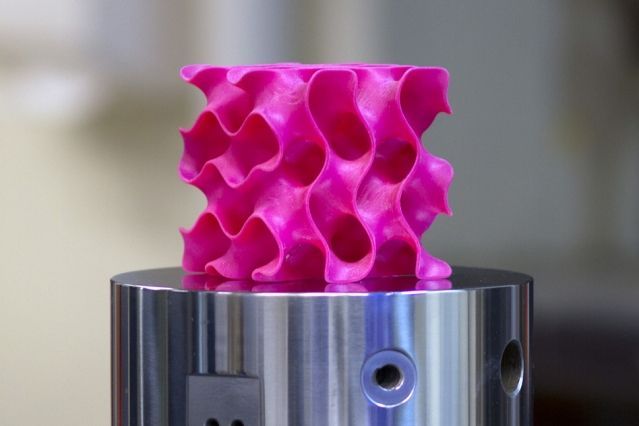

A start-up based in Berkeley, California, polySpectra, is attempting to make better materials for 3D printing. Their inaugural material, COR Alpha, promises to be a stronger and more durable material for digital light processing (DLP) printing. If it’s a compelling fit for your project, you could win $25,000 worth of 3D printing services from polySpectra.

In an attempt to spur the development of 3D printed projects with COR Alpha, polySpectra is holding the Make It Real 3D Printing Challenge. The challenge calls for submissions of designs that could benefit from the new material. The winner will receive $25,000 worth of polySpectra’s 3D printing services in the form of mentoring, design consultation, functional prototyping, qualification, testing and fabrication. Applications are due September 28.

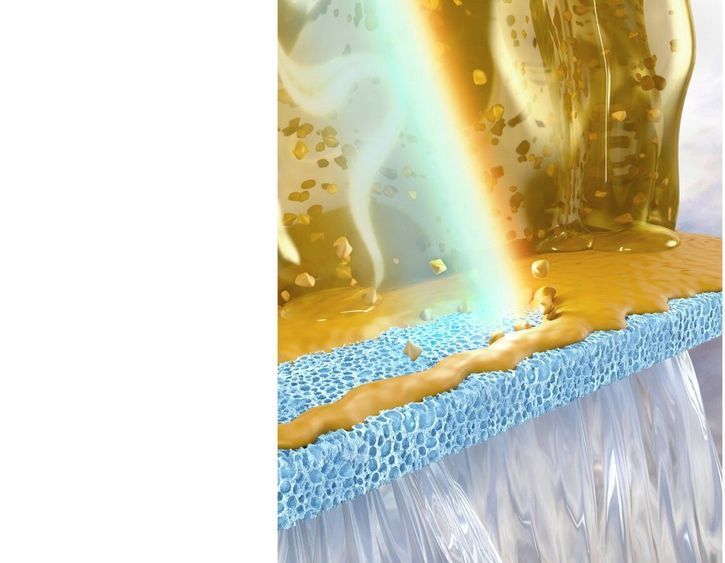

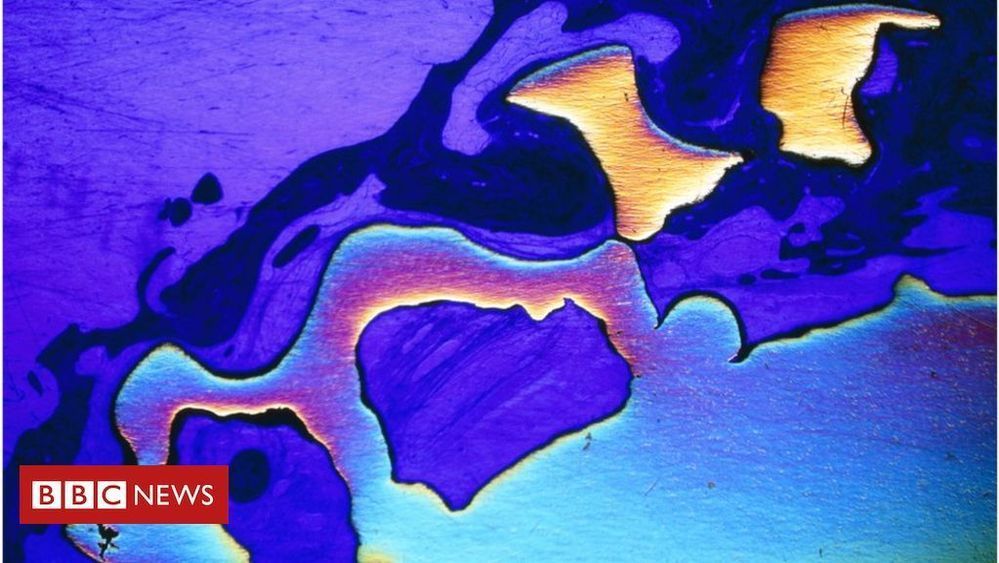

Scientists at the Department of Energy’s (DOE) Argonne National Laboratory have developed a light-activated coating for filtration membranes—the kind used in water treatment facilities, at semiconductor manufacturing sites and within the food and beverage industry—to make them self-cleaning, eliminating the need to shut systems down in order to repair them.

Cheap and effective, water filtration membranes have been around for years but have always been vulnerable to clogging from organic and inorganic materials that stop up its pores over time, a phenomenon known as fouling.

“Anything you stick in water is going to become fouled sooner or later,” said Argonne senior scientist Seth Darling.

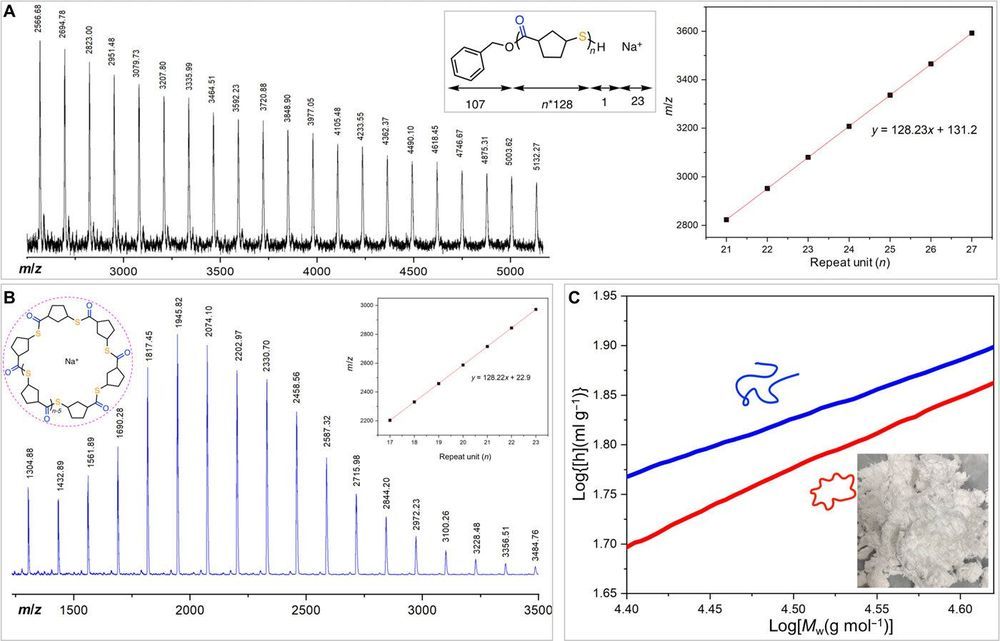

A team of researchers from the U.S., China, and Saudi Arabia has developed a new kind of plastic that is able to maintain its original qualities when recycled. In their paper published in the journal Science Advances, the group describes how the new plastic is made and how well it did when tested for recyclability.

For many years, plastics have been seen as a highly desirable modern advancement—they are light, strong, bendable when needed, and can be used in a very wide variety of applications. The down side to plastics, of course, is that they do not recycle very well and they take a very long time to decay. This has led to millions of tons of plastic waste winding up in landfills and in the water table. Because of that, scientists have been hard a work looking for a new kind of plastic that has all the advantages of the old plastic but also can be easily recycled. In this new effort, the researchers claim to have developed just such a plastic.

The researchers made the new plastic by preparing a bridged bicyclic thiolactone monomer from a bio-based olefin carboxylic acid. The result was a plastic (they called PBTL) that had all the qualities of traditional plastics. They next tested their plastic by conducting bulk depolymerization at 100°C using a catalyst. Testing of the result showed the PBTL had been broken down into its original monomer. They followed that up by breaking down samples of PBTL (using a catalyst) at room temperature. And once again, close examination showed the sample had been broken down to the original monomer.

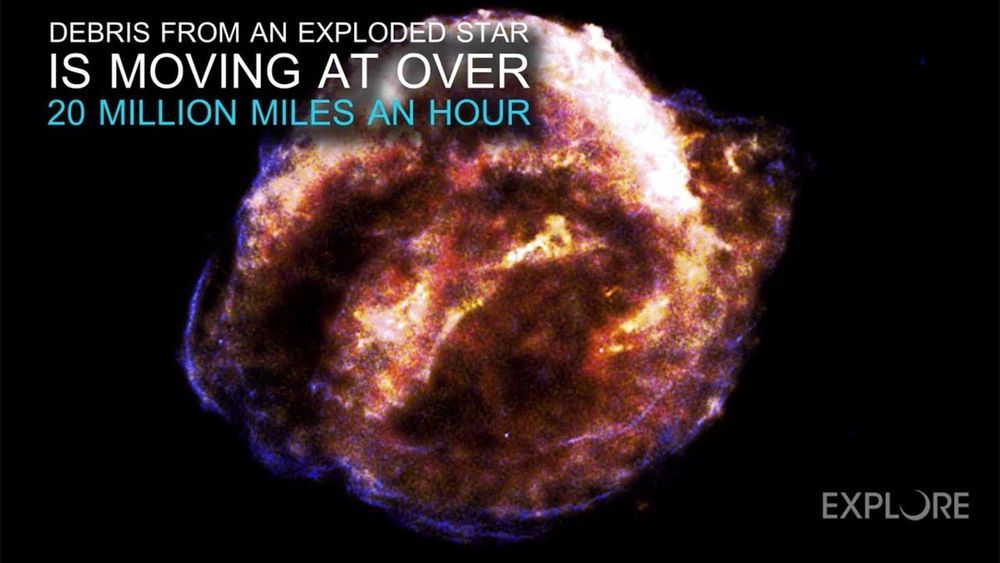

Astronomers have used NASA’s Chandra X-ray Observatory to record material blasting away from the site of an exploded star at speeds faster than 20 million miles per hour. This is about 25,000 times faster than the speed of sound on Earth.

Kepler’s supernova remnant is the debris from a detonated star that is located about 20,000 light years away from Earth in our Milky Way galaxy. In 1604 early astronomers, including Johannes Kepler who became the object’s namesake, saw the supernova explosion that destroyed the star.

We now know that Kepler’s supernova remnant is the aftermath of a so-called Type Ia supernova, where a small dense star, known as a white dwarf, exceeds a critical mass limit after interacting with a companion star and undergoes a thermonuclear explosion that shatters the white dwarf and launches its remains outward.

Circa 2012

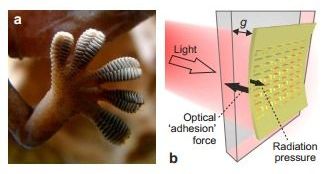

Back in 1871, James Clerk Maxwell predicted that light exerts a force on any surface it hits. This radiation pressure was experimentally discovered some 30 years later and has since emerged as a hugely important force that is now exploited in systems such as solar sails and laser cooling.

Today, John Zhang and buddies at the University of Southampton in the UK go one better. These guys predict that a far more powerful optical force can exist between a metal or dielectric plate and a metamaterial, a substance with optical properties that have been engineered to control light in specific ways.

Metamaterials can be designed so they allow tiny oscillations of electrons called plasmons to exist on their surfaces. The oscillations are tiny–measured in nanometres, that’s about the same as the wavelength of visible light.

Circa 2016

A super-hard metal has been made in the laboratory by melting together titanium and gold.

The alloy is the hardest known metallic substance compatible with living tissues, say US physicists.

The material is four times harder than pure titanium and has applications in making longer-lasting medical implants, they say.

DARPA has awarded a contract for the next phase of development of its Ocean of Things (OoT), a project to seed the seas with thousands of floating sensors, monitoring everything that passes from aircraft to submarines.

The name is a play on the Internet of Things and the aim is to achieve persistent maritime situational awareness over large ocean areas. While satellites can provide some information, DARPA project manager John Waterson points out that there are gaps in their coverage – optical satellites cannot see through clouds, radar satellites only have limited coverage, and none of them can say much about what is going on underwater.

Floating sensors, known as floats, can gather far more detailed information, and can remain at sea for months at a time. There is a network of almost 4,000 Argo science floats around the world, gathering data on ocean temperature and salinity. Waterson wants to see much larger arrays of low-cost floats with more sensors, floats which would carry out missions lasting up to a year before scuttling themselves and degrading. The floats are environmentally friendly, avoiding the use of toxic materials.

Technology that can convert salty seawater or brackish water into safe, clean drinking water has the potential to transform millions of lives across the globe, which is why so many scientists are busy working on projects to do just that.

Now, a new innovation developed by scientists in Australia could be the most promising one yet, with researchers using metal-organic framework compounds (or MOFs) together with sunlight to purify water in just half an hour, using a process that’s more efficient than existing techniques.

It’s cheap, it’s stable, it’s reusable, and it produces water that meets the World Health Organisation (WHO) standards for desalination. Around 139.5 litres (nearly 37 gallons) of clean water can be produced per day from a kilogram (2.2 pounds) of MOF material, based on early testing.