A team of researchers affiliated with several institutions in Germany has developed new chemistry for improved control of the volume of liquid in volumetric additive manufacturing. In their paper published in the journal Nature, the group describes their process and how well it worked when tested.

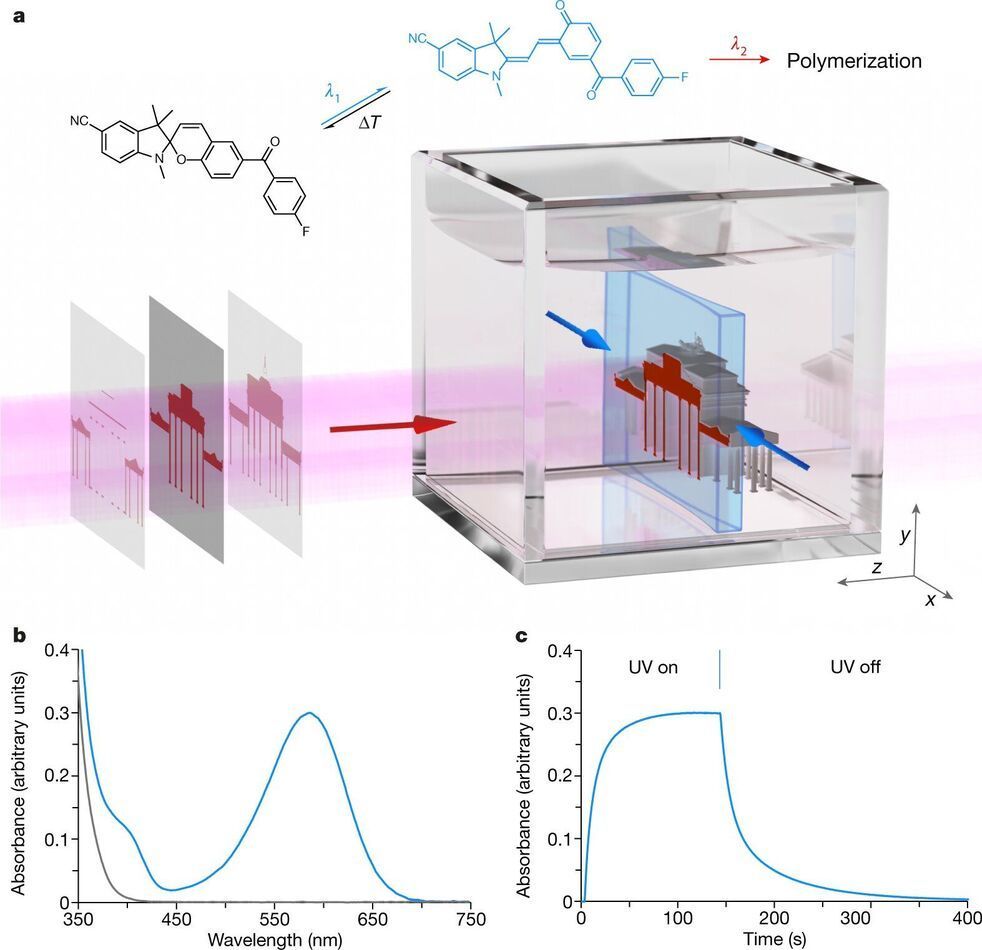

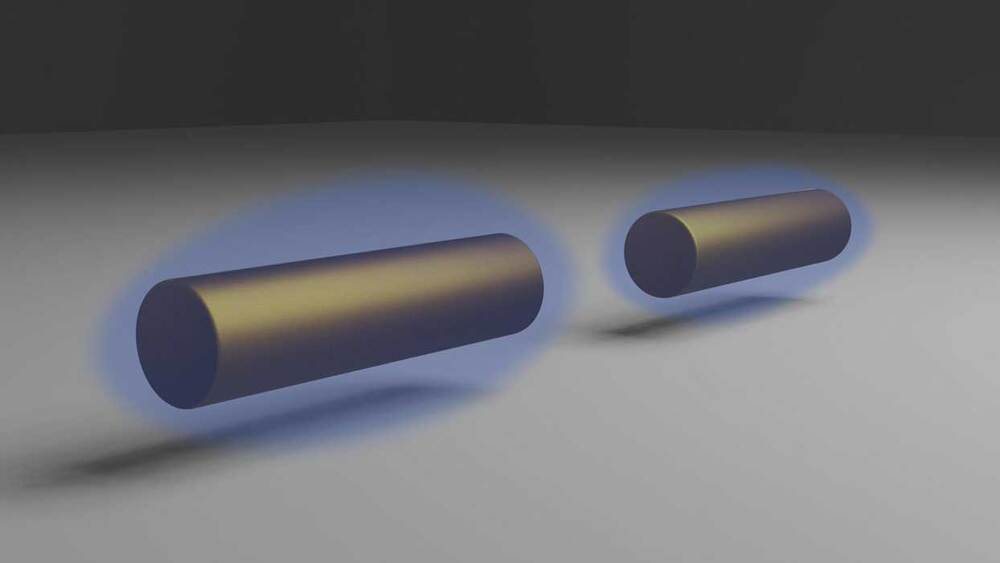

Three-dimensional printing has made many headlines over the past decade as it has revolutionized the manufacturing process for a wide variety of products. Most 3D printing involves controlling gantries that work together to position a nozzle that applies different types of material to a base to build products. More recently, some new types of 3D printers have been developed for volumetric additive manufacturing, or VAM, that use laser light to induce polymerization in a liquid precursor to create products. They work by building products a layer at a time. In this new effort, the researchers have improved the way that polymerization starts in VAM applications. By adding the ability to control the volume of liquid precursor involved in the initiation process, they were able to increase the resolution of VAM printing by 10 times. They call their newly improved process xolography because it involves the use of two crossing light beams to solidify a desired object.

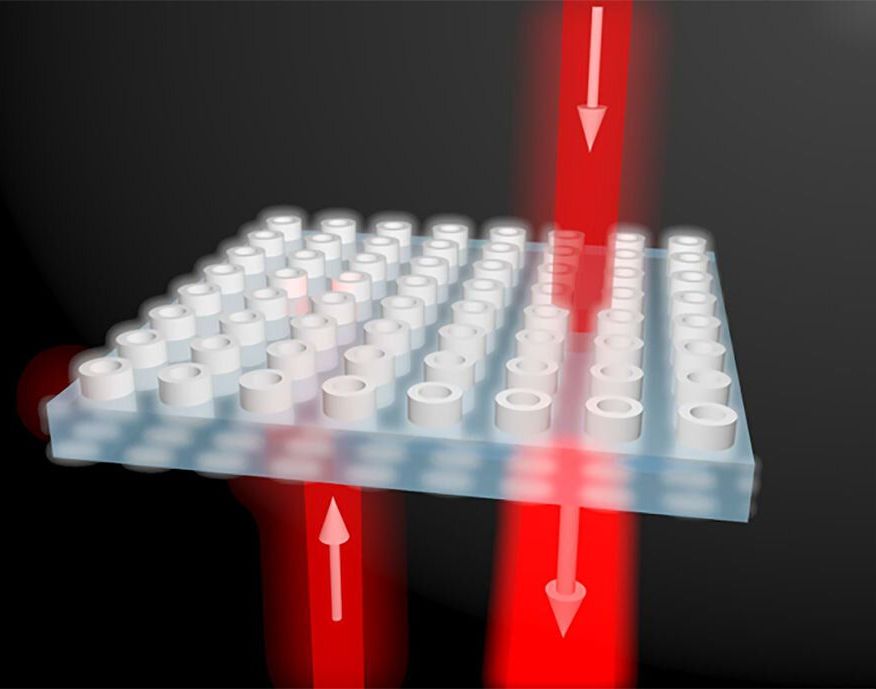

The process begins with creating a rectangular sheet of light using a laser fired into a tub of liquid precursor. The laser excites the precursor molecules inside of the rectangle, preparing them for the second beam of light. The second laser is then directed into the rectangle as a preformed image slice. When the slice is projected into the rectangle, the excited precursor molecules solidify into a polymer, forming a solidified slice. The resin volume is then moved (the light sheet remains fixed in place) so that the process can be repeated to create another slice. The overall process is repeated, creating more slices as it goes, until the desired shape is achieved.