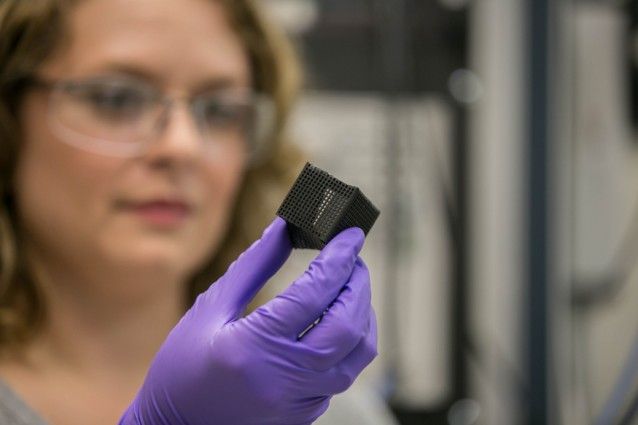

Spider silk is well-known for its unusual combination of being both lightweight and extremely strong—in some cases, stronger than steel. Due to these properties, researchers have been developing spider-silk-inspired materials for potential applications such as durable yet lightweight clothing, bullet-proof vests, and parachutes.

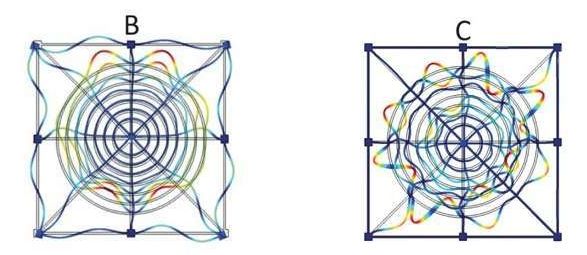

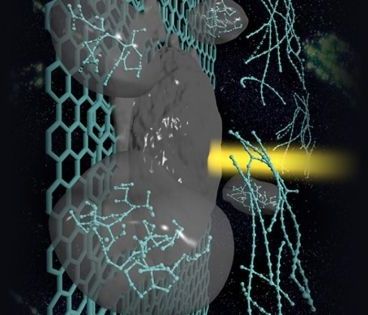

But so far, the acoustic properties of spider webs have not yet been explored. Now in a new study, a team of researchers from Italy, France and the UK has designed an acoustic metamaterial (which is a material made of periodically repeating structures) influenced by the intricate spider web architecture of the golden silk orb-weaver, also called the Nephila spider.

“There has been much work in the field of metamaterials in recent years to find the most efficient configurations for wave attenuation and manipulation,” coauthor Federico Bosia, a physicist at the University of Torino in Italy, told Phys.org. “We have found that the spider web architecture, combined with the variable elastic properties of radial and circumferential silk, is capable of attenuating and absorbing vibrations in wide frequency ranges, despite being lightweight.”

Read more