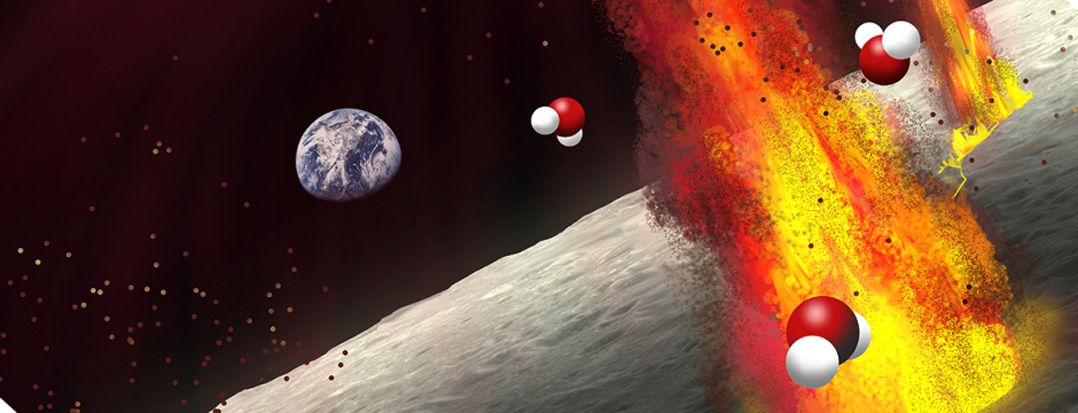

Previously, scientists from Brown detected trace amounts of water in similar volcanic samples — which are composed of loose material or “glass beads” — brought back to Earth from the Apollo 15 and 17 missions. However, the Apollo samples were not collected from the large pyroclastic deposits mapped using the satellite data in the recent study. This brought into question whether the Apollo samples represent a large portion of the moon’s “wet” interior or if they represent only a small water-rich region within an otherwise “dry” mantle.

Related: Moon Express Reveals Bold New Plan to Explore Solar System

“Our work shows that nearly all of the large pyroclastic deposits also contain water, so this seems to be a common characteristic of magmas that come from the deep lunar interior,” Milliken said. “That is, most of the mantle of the moon may be ‘wet.’”.