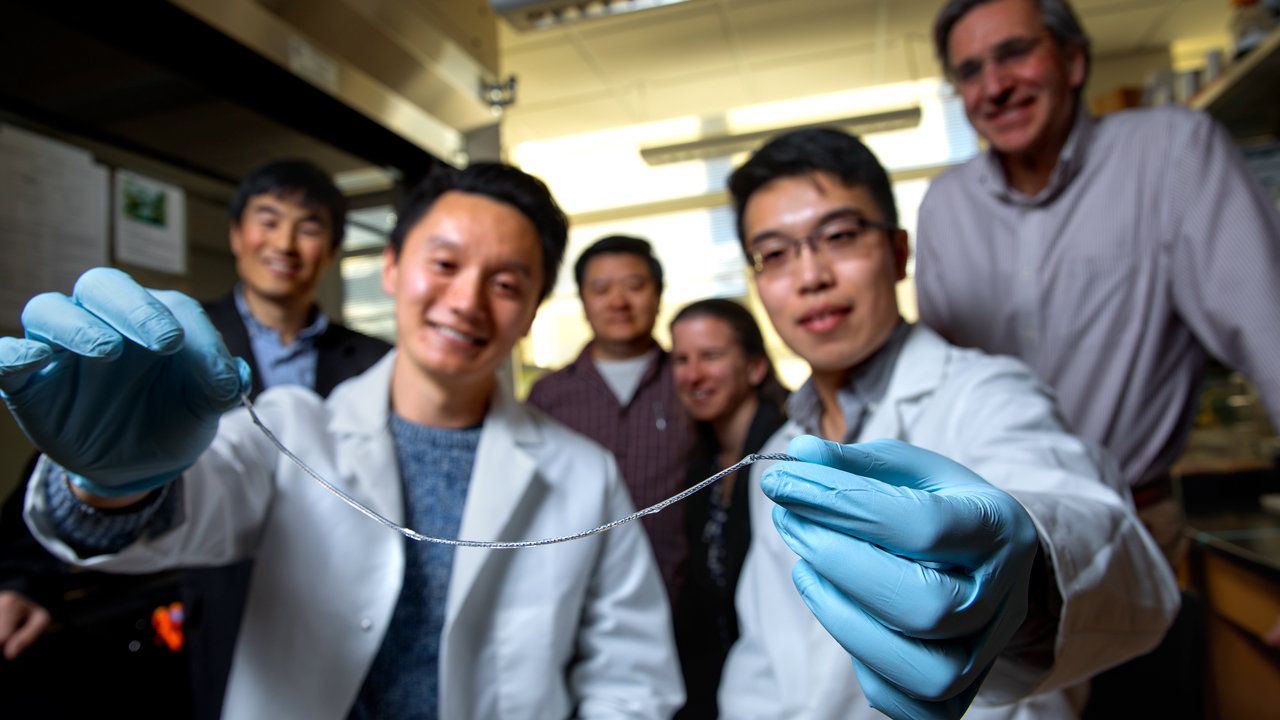

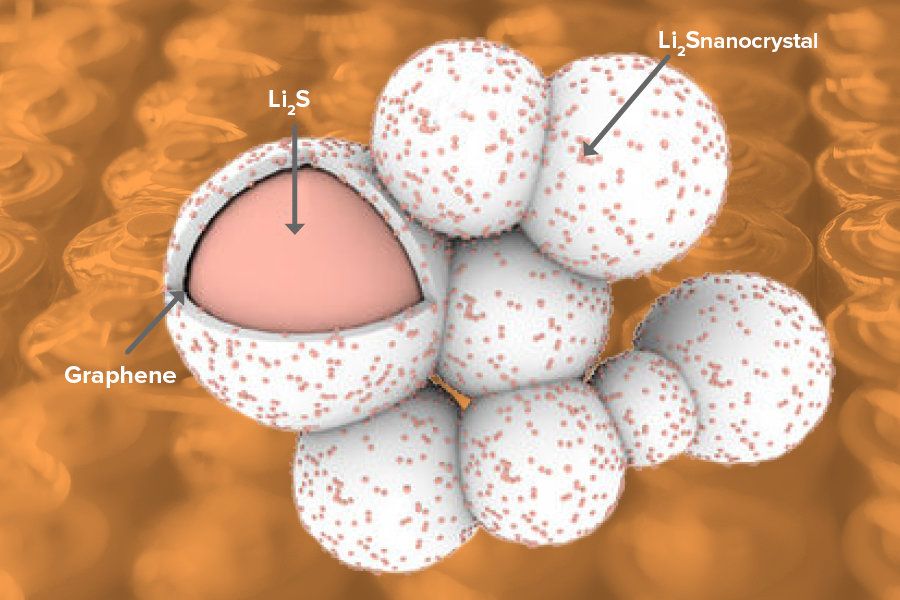

Every year, millions of people around the world die from drinking unclean water. Now, researchers have developed a process that can purify water, no matter how dirty it is, in a single step. Scientists from Australian research organization CSIRO have created a filtration technique using a graphene film with microscopic nano-channels that lets water pass through, but stops pollutants. The process, called “Graphair”, is so effective that water samples from Sydney Harbor were safe to drink after being treated.

And while the film hails from graphene, Graphair is comparatively cheaper, faster and more environmentally-friendly to make, as its primary component is renewable soybean oil, which also helps maximise the efficiency of the purifying technique’s filter counterpart. Over time, oil-based pollutants can impede water filters, so contaminants have to be removed before filtering can even begin, but using Graphair removes these pollutants faster than any other method.

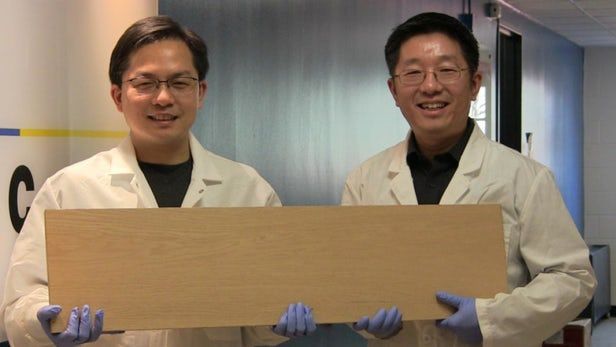

Water purification usually involves a complex process of several steps, so this breakthrough could have a significant impact on the some 2.1 billion people who don’t have clean, safe drinking water. “All that’s needed is heat, our graphene, a membrane filter and a small water pump. We’re hoping to commence field trials in a developing world community next year,” said lead author Dr Dong Han Seo, who added that the team is looking for industry partners to help scale up the technology, and is also working on other applications for Graphair, such as seawater and industrial effluents.