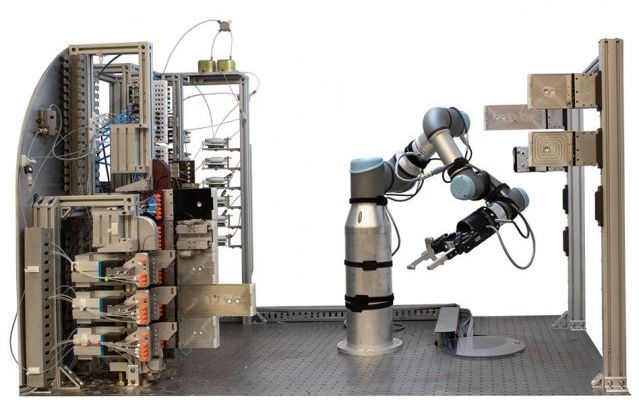

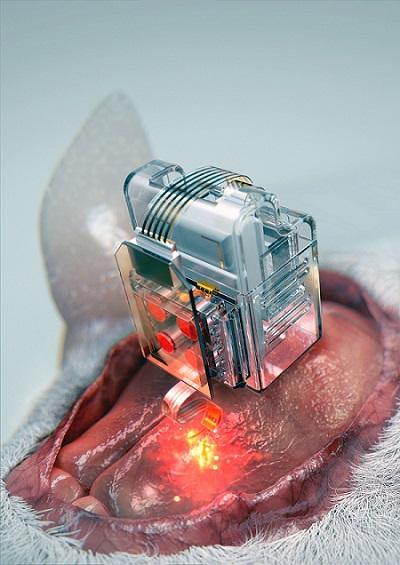

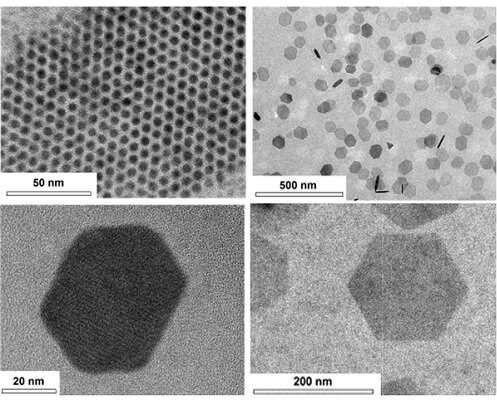

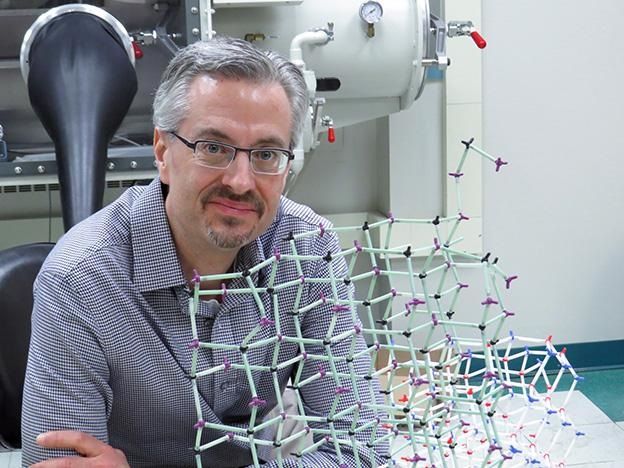

Guided by artificial intelligence and powered by a robotic platform, a system developed by MIT researchers moves a step closer to automating the production of small molecules. Images: Connor Coley, Felice Frankel.

The system, described in the August 8 issue of Science, could free up bench chemists from a variety of routine and time-consuming tasks, and may suggest possibilities for how to make new molecular compounds, according to the study co-leaders Klavs F. Jensen, the Warren K. Lewis Professor of Chemical Engineering, and Timothy F. Jamison, the Robert R. Taylor Professor of Chemistry and associate provost at MIT.

The technology “has the promise to help people cut out all the tedious parts of molecule building,” including looking up potential reaction pathways and building the components of a molecular assembly line each time a new molecule is produced, says Jensen.