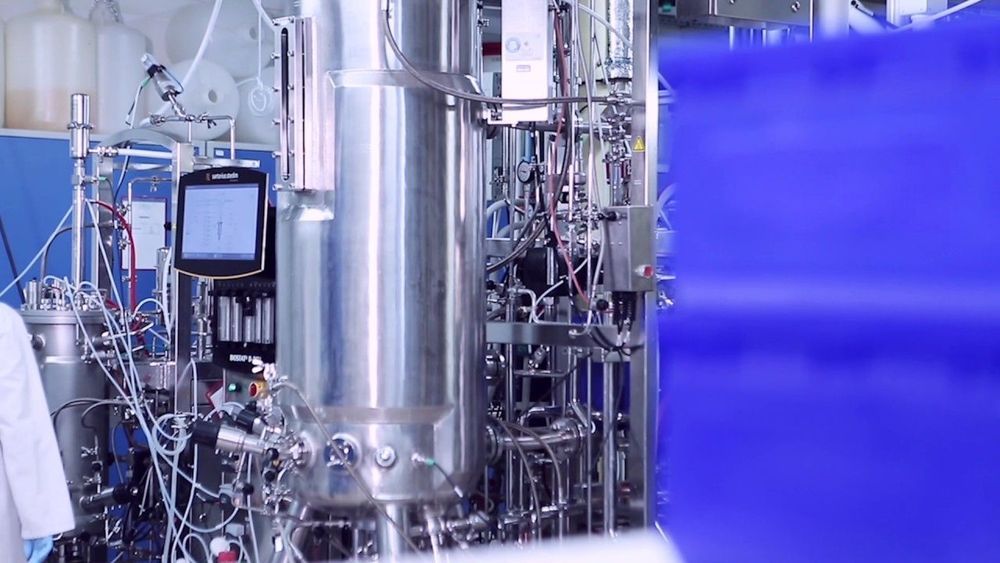

Using a new time-based method to control light from an ultrafast laser, researchers have developed a nanoscale 3D printing technique that can fabricate tiny structures 1000 times faster than conventional two-photon lithography (TPL) techniques, without sacrificing resolution.

Despite the high throughput, the new parallelized technique—known as femtosecond projection TPL (FP-TPL)—produces depth resolution of 175 nanometers, which is better than established methods and can fabricate structures with 90-degree overhangs that can’t currently be made. The technique could lead to manufacturing-scale production of bioscaffolds, flexible electronics, electrochemical interfaces, micro-optics, mechanical and optical metamaterials, and other functional micro- and nanostructures.

The work, reported Oct. 3 in the journal Science, was done by researchers from Lawrence Livermore National Laboratory (LLNL) and The Chinese University of Hong Kong. Sourabh Saha, the paper’s lead and corresponding author, is now an assistant professor in the George W. Woodruff School of Mechanical Engineering at the Georgia Institute of Technology.