In an incredible feat of remote engineering, NASA has fixed one of the most intrepid explorers in human history.

Thanks to some (very) remote engineering work by NASA, the intrepid explorer’s science mission is back on.

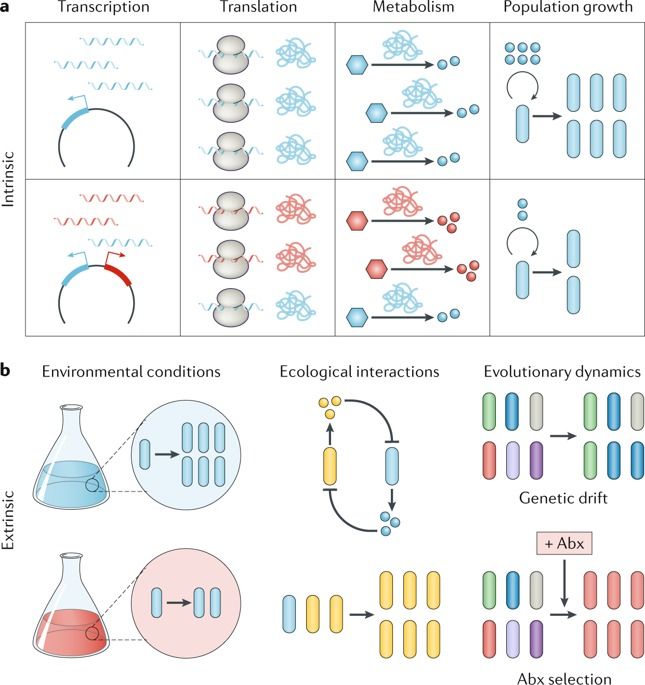

Predictive biology is the next great chapter in synthetic and systems biology, particularly for microorganisms. Tasks that once seemed infeasible are increasingly being realized such as designing and implementing intricate synthetic gene circuits that perform complex sensing and actuation functions, and assembling multi-species bacterial communities with specific, predefined compositions. These achievements have been made possible by the integration of diverse expertise across biology, physics and engineering, resulting in an emerging, quantitative understanding of biological design. As ever-expanding multi-omic data sets become available, their potential utility in transforming theory into practice remains firmly rooted in the underlying quantitative principles that govern biological systems. In this Review, we discuss key areas of predictive biology that are of growing interest to microbiology, the challenges associated with the innate complexity of microorganisms and the value of quantitative methods in making microbiology more predictable.

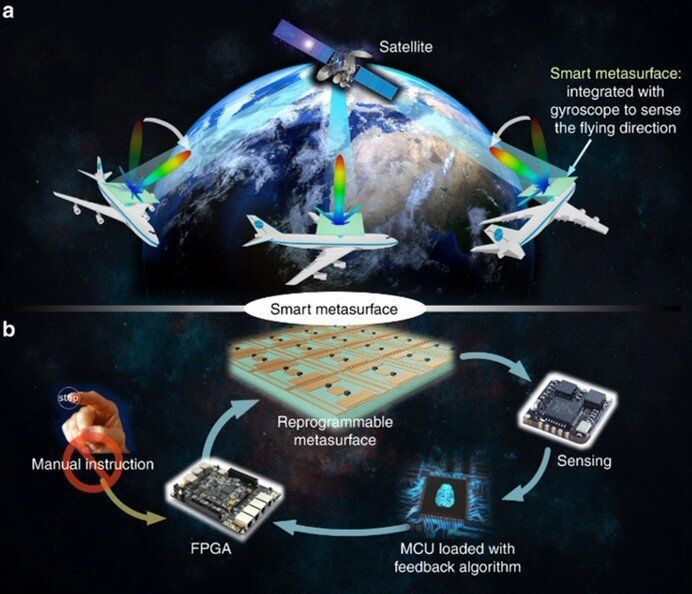

Materials scientists aim to engineer intelligence into the fabric of materials or metamaterials for programmable functions. Engineering efforts can vary from passive to active forms to develop programmable metasurfaces using dynamic and arbitrary electromagnetic (EM) wavefields. Such metasurfaces, however, require manual control to switch between functions. In a new study now published on Light: Science & Applications, Qian Ma and an interdisciplinary research team in the State Key Laboratory, Cyberspace Science and Technology, and the Department of Electronics in China engineered a smart metasurface for self-adaptive programmability.

A few minutes into the life of the universe, colliding emissions of light energy created the first particles of matter and antimatter. We are familiar with the reverse process—matter generating energy—in everything from a campfire to an atomic bomb, but it has been difficult to recreate that critical transformation of light into matter.

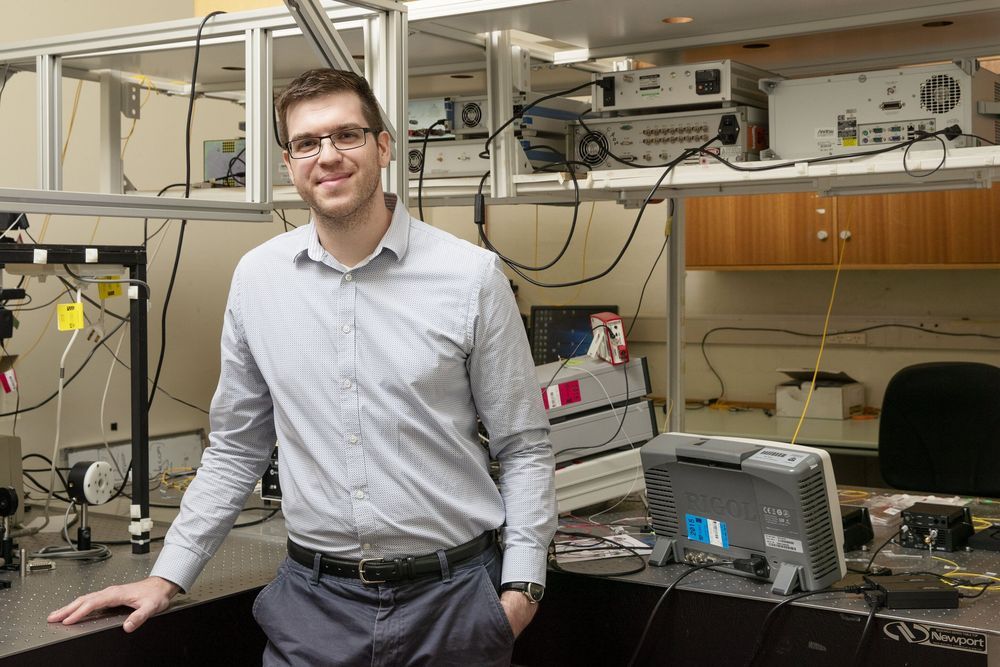

Now, a new set of simulations by a research team led by UC San Diego’s Alexey Arefiev point the way toward making matter from light. The process starts by aiming a high-power laser at a target to generate a magnetic field as strong as that of a neutron star. This field generates gamma ray emissions that collide to produce—for the very briefest instant—pairs of matter and antimatter particles.

The study, published May 11 in Physical Review Applied offers a sort of recipe that experimentalists at the Extreme Light Infrastructure (ELI) high-power laser facilities in Eastern Europe could follow to produce real results in one to two years, said Arefiev, an associate professor of mechanical and aerospace engineering.

Eric Klien

A liquid metal lattice that can be crushed but returns to its original shape on heating has been developed by Pu Zhang and colleagues at Binghamton University in the US. The material is held together by a silicone shell and could find myriad uses including soft robotics, foldable antennas and aerospace engineering. Indeed, the research could even lead to the creation of a liquid metal robot evoking the T-1000 character in the film Terminator 2.

The team created the liquid metal lattice using a special mixture of bismuth, indium and tin known as Field’s alloy. This alloy has the relatively unusual property of melting at just 62 °C, which means it can be liquefied with just hot water. Field’s alloy already has several applications – including as a liquid-metal coolant for advanced nuclear reactors.

Zhang and colleagues combined the alloy with a silicone shell through a complex hybrid manufacturing process that combines 3D printing, vacuum casting and so-called “conformal coating” – a technique normally used to coat circuit boards in a thin polymer layer to protect them against the environment. The silicone shell is what allows the lattice to “remember” a desired shape and restore such when the alloy is melted.

Scientists have developed a new type of laser that can deliver high amounts of energy in very short bursts of time, with potential applications in eye and heart surgery or the engineering of delicate materials.

The Director of the University of Sydney Institute of Photonics and Optical Science, Professor Martijn de Sterke, said: “This laser has the property that as its pulse duration decreases to less than a trillionth of a second, its energy could go through the roof.

”This makes them ideal candidates for the processing of materials that require short, powerful pulses. One application could be in corneal surgery, which relies on gently removing material from the eye. This requires strong, short light pulses that do not heat and damage the surface.”

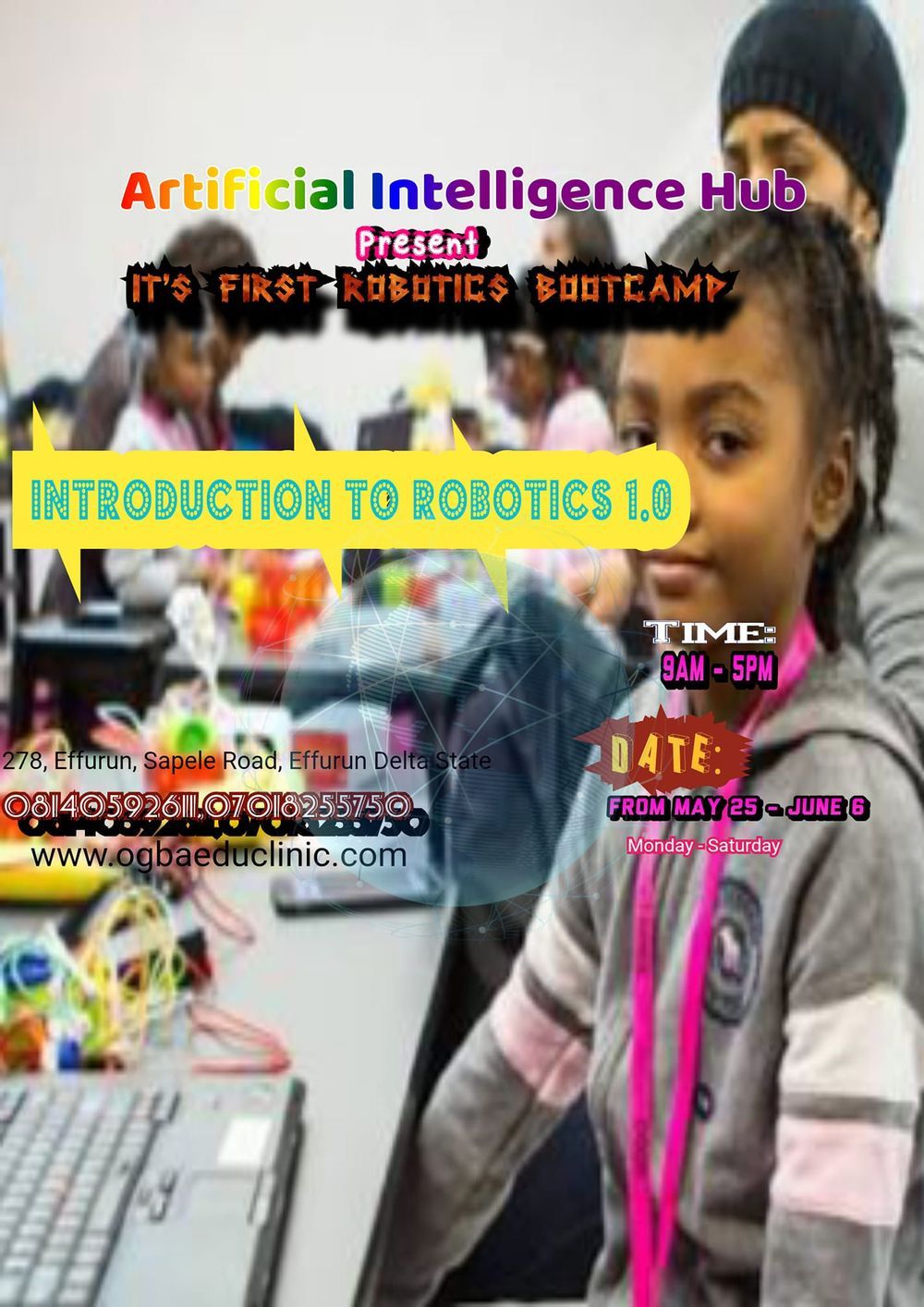

In our efforts to domesticate Artificial Intelligence and prepare people for future jobs in Africa. We are glad to announce our first Robotic boot camp tagged Introduction to Robotics 1.0. The Artificial Intelligence Hub is training young people between the ages 7 and 20 on Robotic Engineering. Take advantage of this opportunity to learn and be equipped with future skills. Register with the link provided below. https://forms.gle/yTx2obDkSQ5ULTLM9

Hoppy beers do that to me. This beer was different. The water used for the brew came not from a river, a reservoir, or even a well. Instead, the water was sourced from a wastewater treatment plant located along the South Platte River. This simple fact didn’t bother me at all.

To be clear, I’m not a risk taker. Never skydived. Never paddled down Class V rapids. Never swallowed goldfish on a dare. But from what I’ve learned about purification processes for reclaimed water, drinking this limited-edition beer was eminently safe. The pilsner, blonde and translucent, like a Coors, looked and tasted like any number of beers made from water freshly obtained from creeks and rivers tumbling from Colorado’s mountain peaks. As for the strawberry-kiwi wheat beer ordered by my companion, I would have nothing of it. “That’s not beer,” I harrumphed, “that’s a fruit bowl. Undrinkable.”

I was at Declaration Brewing Co., located in Denver’s Overland neighborhood. The brewery and also a winery, InVINtions, located in Greenwood Village, were part of a regional effort. Water for the one-time specialty beverages produced by both came from the PureWater Colorado Demonstration Project. In the demonstration that was conducted in spring of 2018, water providers, engineering companies and water reuse advocates collaborated to showcase direct potable reuse treatment technologies. The water was treated using five different processes until it met federal and state drinking water standards, suitable for human consumption.