Startup Emrod is building a system to wirelessly beam power over long distances and plans to test the system with New Zealand’s second largest utility.

All-electric camper vans are still quite rare. Those that are available tend to be designed for camping and commuting locally, not road-tripping indefinitely. But VW fanatic Frank Eusterholz had different ideas. He threw a PlugVan camper module into the e-Crafter cargo van and hit the road … the long road. Eusterholz’s 7,500-km (4,660-mile) journey sent him highway-cruising, switchback-climbing and island-hopping across Europe, from VW van HQ Hannover, Germany to the northernmost tip of Continental Europe. His journey serves as an inspiring early look at the electric RVing possibilities that will only grow with time.

Electric camper vans have been available for years, but a practical version with enough range always seems just a few years off. Next-generation EV campers from the Rivian R1T overland truck to VW’s own ID. Buzz promise more practical ranges and capabilities, but for now e-campers remain limited to small, modest-range minis like the Sussex e-NV200 Camper Car.

In an announcement released last month, Volkswagen painted a different picture of electric camper van touring. It described the story of 54-year-old Frank Eusterholz, a longtime EV driver determined not to let the modest ranges of contemporary electric vans deter him from EV van life. A resident of Samsø, a Danish island that’s been committed to sustainable energy for decades, Eusterholz considered the e-Crafter a natural vehicle choice, and the perfect camper base.

Skeleton Technologies and the Karlsruhe Institute of Technology (KIT) say they have developed a graphene-based battery with a 15-second charging time, as well as charging cycles counted in the hundreds of thousands.

The so-called SuperBattery’s key component is Skeleton’s patented Curved Graphene carbon material, which enables the high power and long lifetime of ultracapacitors to be applied in a graphene battery.

“The SuperBattery is a game-changer for the automotive industry. Together with Li-ion batteries, they have it all: high energy and power density, long lifetime and 15-second charging time,” said Skeleton Technologies CEO Taavi Madiberk.

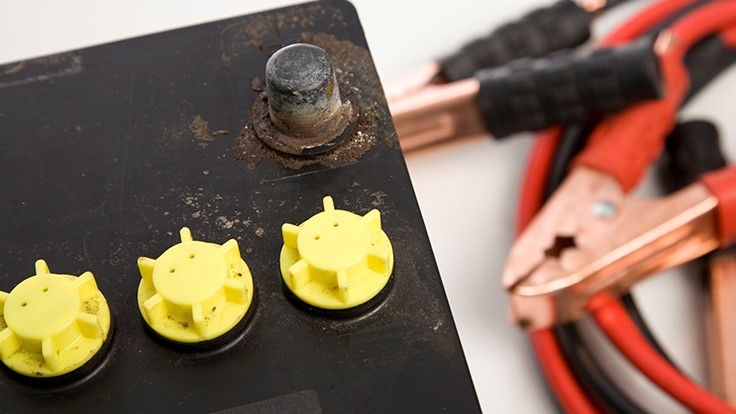

Battery Council International (BCI), Chicago, and Essential Energy Everyday have released a study showing lead batteries have a recycling rate of 99.3 percent, making them the No. 1 recycled consumer product in the U.S.

The groups say the near-perfect rate of recycling is attributed to industry investment in a closed loop collection and recycling system that keeps 1.7 million tons of batteries out of landfills annually.

The National Recycling Rate Study, released in conjunction with America Recycles Day Nov. 15, 2017, demonstrates the sustainability of lead batteries and their role in environmentally friendly energy storage for automotive and industrial applications, say the organizations.

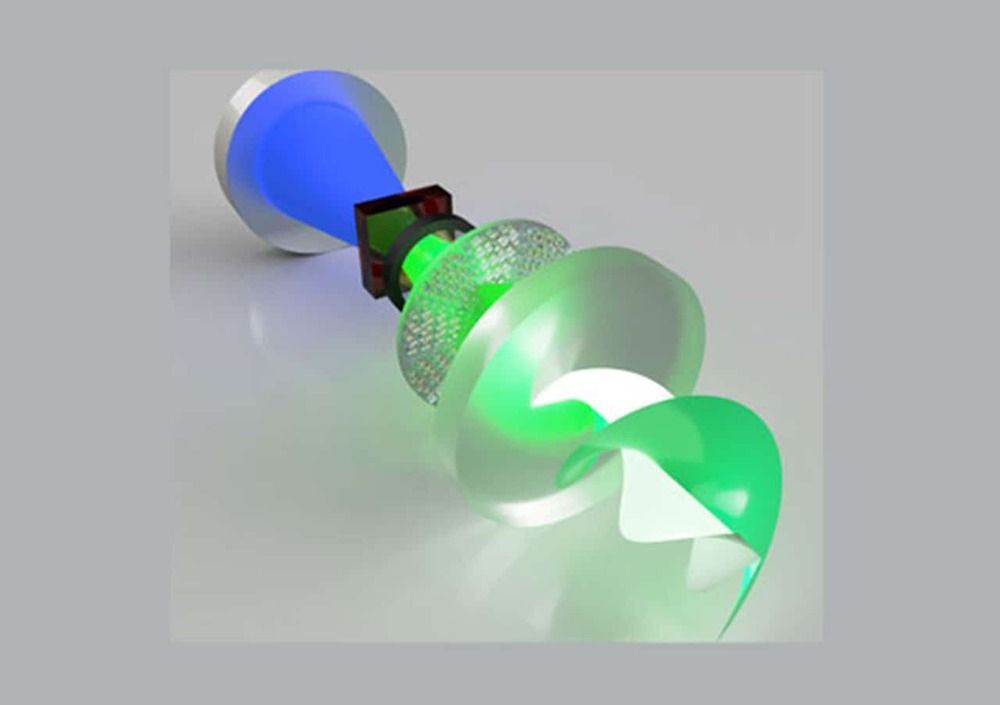

Scientists in collaboration have developed the world’s first metasurface laser that produces “super-chiral light”- the light with ultra-high angular momentum. Also, they have developed a nanostructured metasurface that has the most significant phase gradient ever produced and allows for high power operation in a compact design.

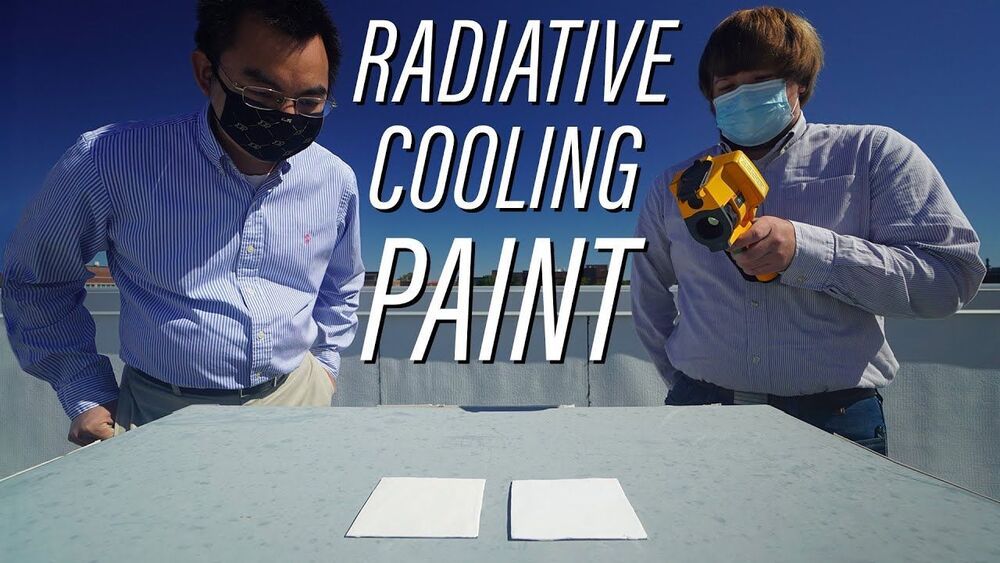

The colors that we choose to paint rooms, houses, or buildings do more than just change the way it looks. Colors can affect one’s mood as well, but it can also have an impact on the overall temperature. This is because different colors absorb light differently, with some colors absorbing light more than others, which is why colors like black are known to retain heat.

In a bid to help reduce the need for air conditioning which can consume a lot of electricity and also release by-product gases into the atmosphere, researchers at Purdue University have developed a special form of white paint that they claim can reduce surface temperatures by up to 18 degrees Fahrenheit compared to their ambient surroundings, thus replicating the effects of a refrigerator but without consuming any energy at all.

This means that by using this paint to help paint buildings or rooms, it could drastically reduce the temperature in a room, which in turn reduces the need for appliances like air conditioning, or at least to the point where we can reduce how long we run them for. By helping cool down buildings, it can work in tandem with heating/cooling systems where if the building remains cool enough, then there won’t be a need for the air conditioning to kick in.

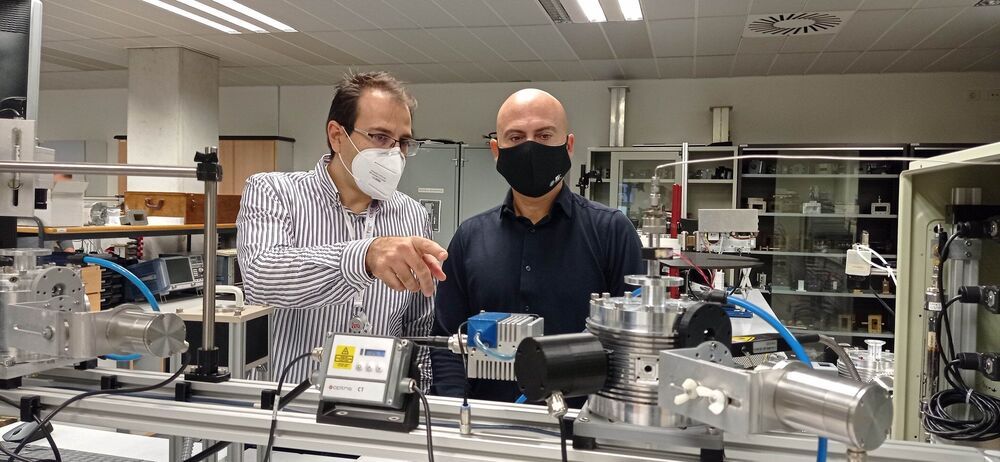

A team of researchers from the Polytechnic University of Valencia and the Spanish National Research Council (CSIC) has discovered a new method that makes it possible to transform electricity into hydrogen or chemical products solely using microwaves—without cables and without any type of contact with electrodes. This represents a revolution in the field of energy research and a key development for the process of industrial decarbonisation, as well as for the future of the automotive sector and the chemical industry, among many others. The study has been published in the latest edition of Nature Energy, where the discovery is explained.

The technology developed and patented by the UPV and CSIC is based on the phenomenon of the microwave reduction of solid materials. This method makes it possible to carry out electrochemical processes directly without requiring electrodes, which simplifies and significantly cheapens its practical use, as it provides more freedom in the design of the structure of the device and choosing the operation conditions, mainly the temperature. It is a technology with great practical potential, especially for its use in storing energy and producing synthetic fuels and green chemical products. This aspect has significant importance today, as both transportation and industry are immersed in a transition to decarbonise, meaning they have to meet very demanding goals between 2030 and 2040 to decrease the consumption of energy and substances from fossil sources, mainly natural gas and oil, highlights José Manuel Serra, research lecturer of the CSIC at the Chemical Technology Institute.

Nylon might seem the obvious go-to material for electronic textiles—not only is there an established textiles industry based on nylon, but it conveniently has a crystalline phase that is piezoelectric—tap it and you get a build-up of charge perfect for pressure sensing and harvesting energy from ambient motion.

Unfortunately, forming nylon into fibers while getting it to take on the crystal structure that has a piezoelectric response is not straightforward. “This has been a challenge for almost half a century,” explains Kamal Asadi, a researcher at the Max-Planck Institute for Polymer Research, Germany, and professor at the University of Bath, U.K. In a recent Advanced Functional Materials report, he and his collaborators describe how they have now finally overcome this.

The piezoelectric phase of nylon holds appeal not just for electronic textiles but all kinds of electronic devices, particularly where there is demand for something less brittle than the conventional piezoelectric ceramics. However, for decades, the only way to produce nylon with the crystalline phase that has a strong piezoelectric response has been to melt it, rapidly cool it and then stretch it so that it sets into a smectic δ’ phase. This produces slabs typically tens of micrometers thick—far too thick for applications in electronic devices or electronic textiles.