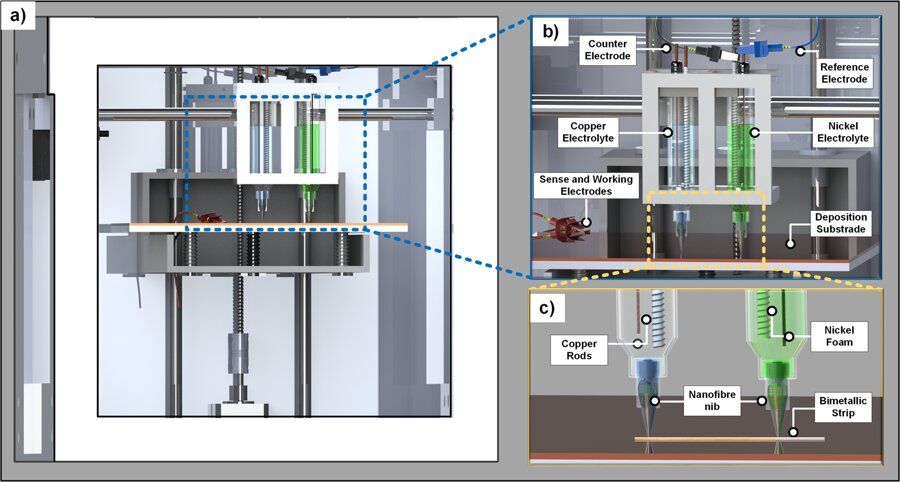

Four-dimensional (4D) printing can create complex 3D geometries that react to environmental stimuli, opening new design opportunities in materials science. A vast majority of 4D printing approaches use polymer materials, which limit the operational temperature during the process of engineering. In a recent study, Xiaolong Chen and co- workers at the Dyson School of Design and Engineering, Department of Earth Science and Engineering and Department of Materials at the Imperial College of London, U.K., developed a new multi-metal electrochemical 3D printer. The device was able to construct bimetallic geometries by selectively depositing different metals with temperature-responsive behavior programmed into the printed structure. In the study, they demonstrated a meniscus confined electrochemical 3D printing approach using a multi-print head design and nickel and copper materials as examples, the ability can be transferred to other deposition solutions. The results are now published in Scientific Reports.

4D printing multi-metal products with a desktop electrochemical 3D printer

Read more