Researchers from the Ruhr University Bochum (RUB) and the University of Warwick were able to observe the smallest details of hydrogen production with the synthetic mineral pentlandite. This makes it possible to develop strategies for the design of robust and cost-effective catalysts for hydrogen production. The working groups of Prof. Wolfgang Schuhmann and Dr. Ulf-Peter Apfel from the RUB and the team headed by Prof. Patrick R. Unwin from the University of Warwick published their results in the journal Angewandte Chemie.

Hydrogen gas is considered a possible future source of energy and can be produced from water using platinum catalysts and electricity. However, researchers seek alternative catalysts made of cheaper and more readily available materials with equally high efficiency. There are a number of materials that, like platinum, are able to catalyse the reaction of water into hydrogen. “These include metal chalcogenides such as the mineral pentlandite, which is just as efficient as platinum and is also significantly more stable toward catalyst poisons such as sulphur,” explains Ulf-Peter Apfel. Pentlandite consists of iron, nickel and sulphur. Its structure is similar to that of the catalytic centres of hydrogen-producing enzymes found in a variety of sources, including green algae.

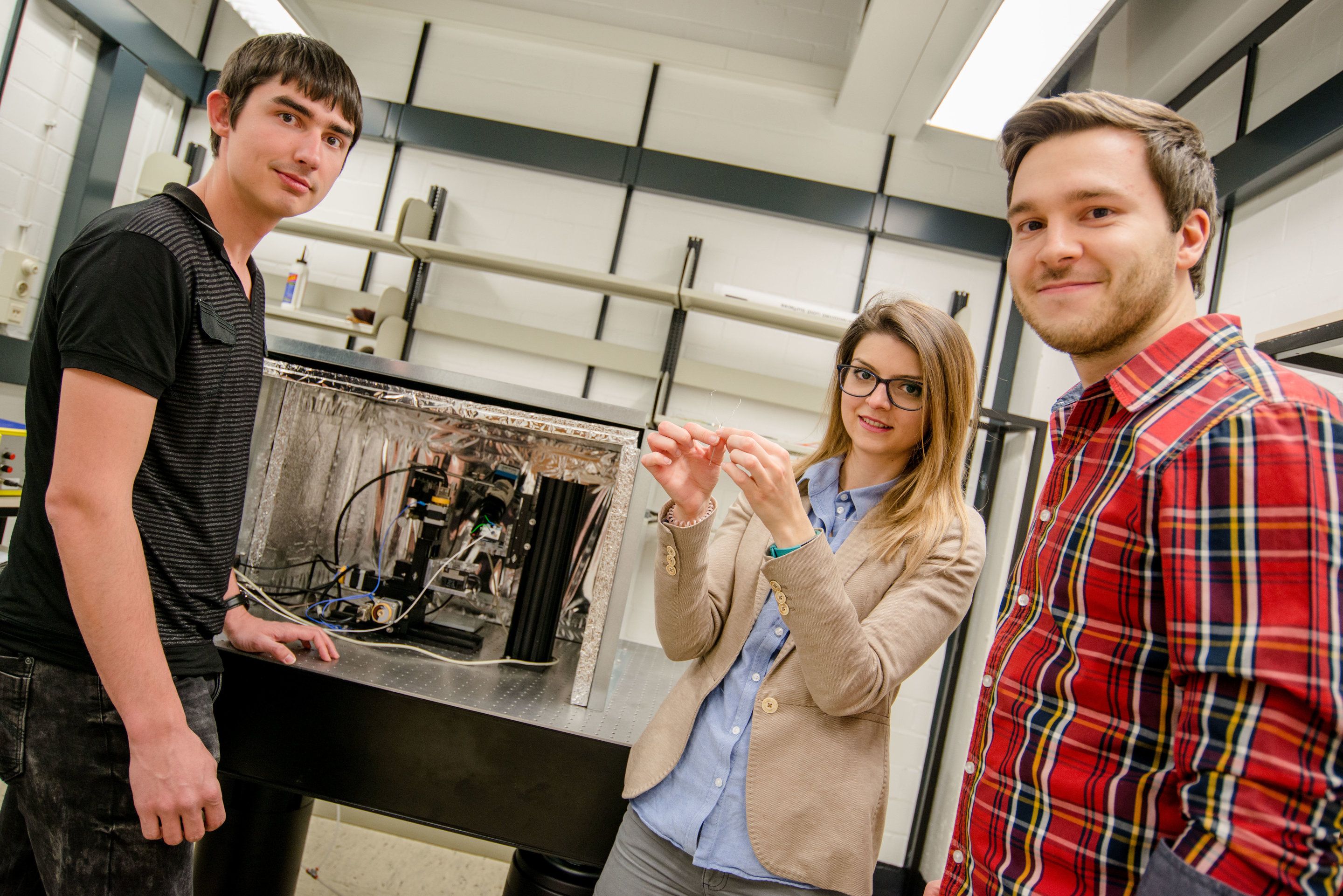

In the current study, the researchers investigated hydrogen production rates of artificially prepared crystalline surfaces of the mineral pentlandite in a drop of liquid with a diameter of a few hundred nanometres. They used scanning electrochemical cell microscopy for this purpose.