Technology can be confusing when it begins moving at such an accelerated rate, perfectly exemplified by the 3D industry, and encompassing all that goes with it, from 3D scanning to 3D printing and then peripheral industries that are often connected too such as augmented and virtual realities. We’ve barely digested all the stunning innovations making impacts in so many different sectors, from 3D printed medical models that allow for more complex surgeries, to 3D printed parts for a suspension system that make racing bikes go faster, all the way to incredible toys for your kids using augmented reality systems.

Technology can be confusing when it begins moving at such an accelerated rate, perfectly exemplified by the 3D industry, and encompassing all that goes with it, from 3D scanning to 3D printing and then peripheral industries that are often connected too such as augmented and virtual realities. We’ve barely digested all the stunning innovations making impacts in so many different sectors, from 3D printed medical models that allow for more complex surgeries, to 3D printed parts for a suspension system that make racing bikes go faster, all the way to incredible toys for your kids using augmented reality systems.

Yet, while work is definitely just beginning in the 3D realm, scientists have already begun exploring a range of uses for 4D technology that should prove offer impacts in just as many applications, from the medical field to electronics and far beyond. It might seem like a lot all at once, but the two technologies definitely work together, with the 4D emphasis adding a more intuitive, smart angle to fabrication.

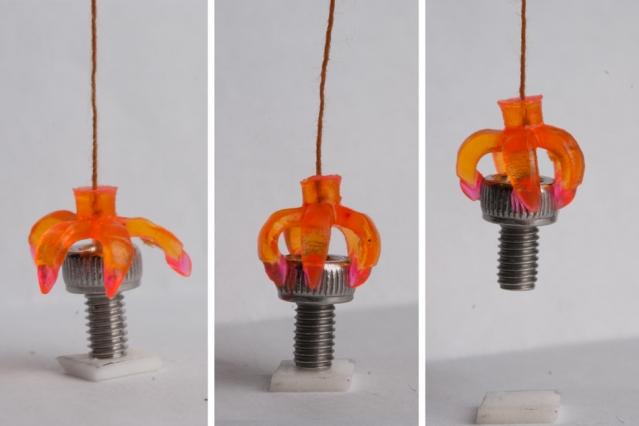

As we’ve seen in other studies using the application of heat, it would appear that 3D printed objects can be treated or manipulated to cause shapes to morph according to their environment, as well as remembering their previous state and going back to it in the appropriate conditions. Now, teams from both MIT and the Singapore University of Technology and Design (SUTD) are employing light in their endeavors to create smart structures. They’ve had good success too, if the amount of torturing they’ve put these materials through is any indication. According to the engineers, they’ve twisted, bent, and stretched everything from small coils to flowers fabricated out of numerous materials, and even a replica they made of the Eiffel tower. As is the case with structures being pushed into the 4D realm, all of the above materials reverted.