Rutgers engineers have created a highly effective way to paint complex 3D-printed objects, such as lightweight frames for aircraft and biomedical stents, that could save manufacturers time and money and provide new opportunities to create “smart skins” for printed parts.

The findings are published in the journal ACS Applied Materials & Interfaces.

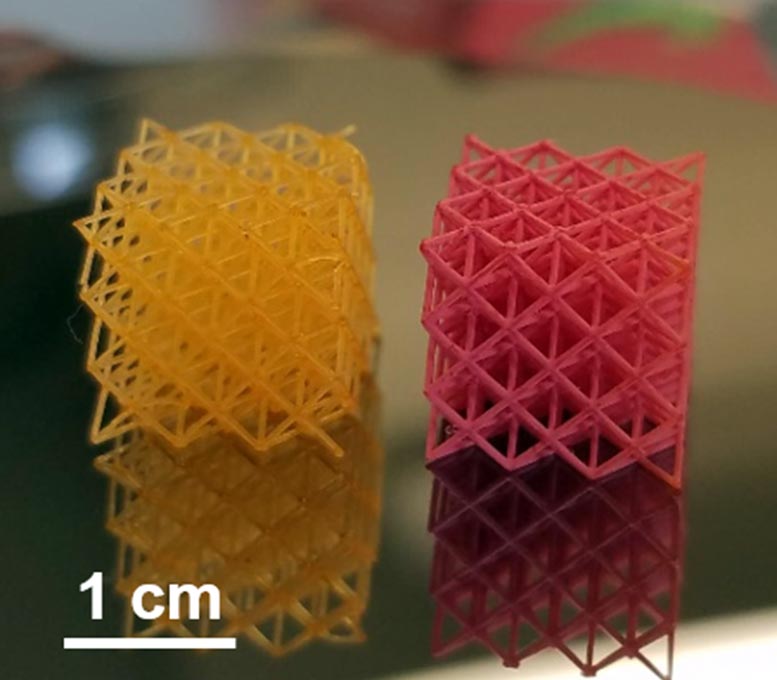

Conventional sprays and brushes can’t reach all nooks and crannies in complex 3D-printed objects, but the new technique coats any exposed surface and fosters rapid prototyping.